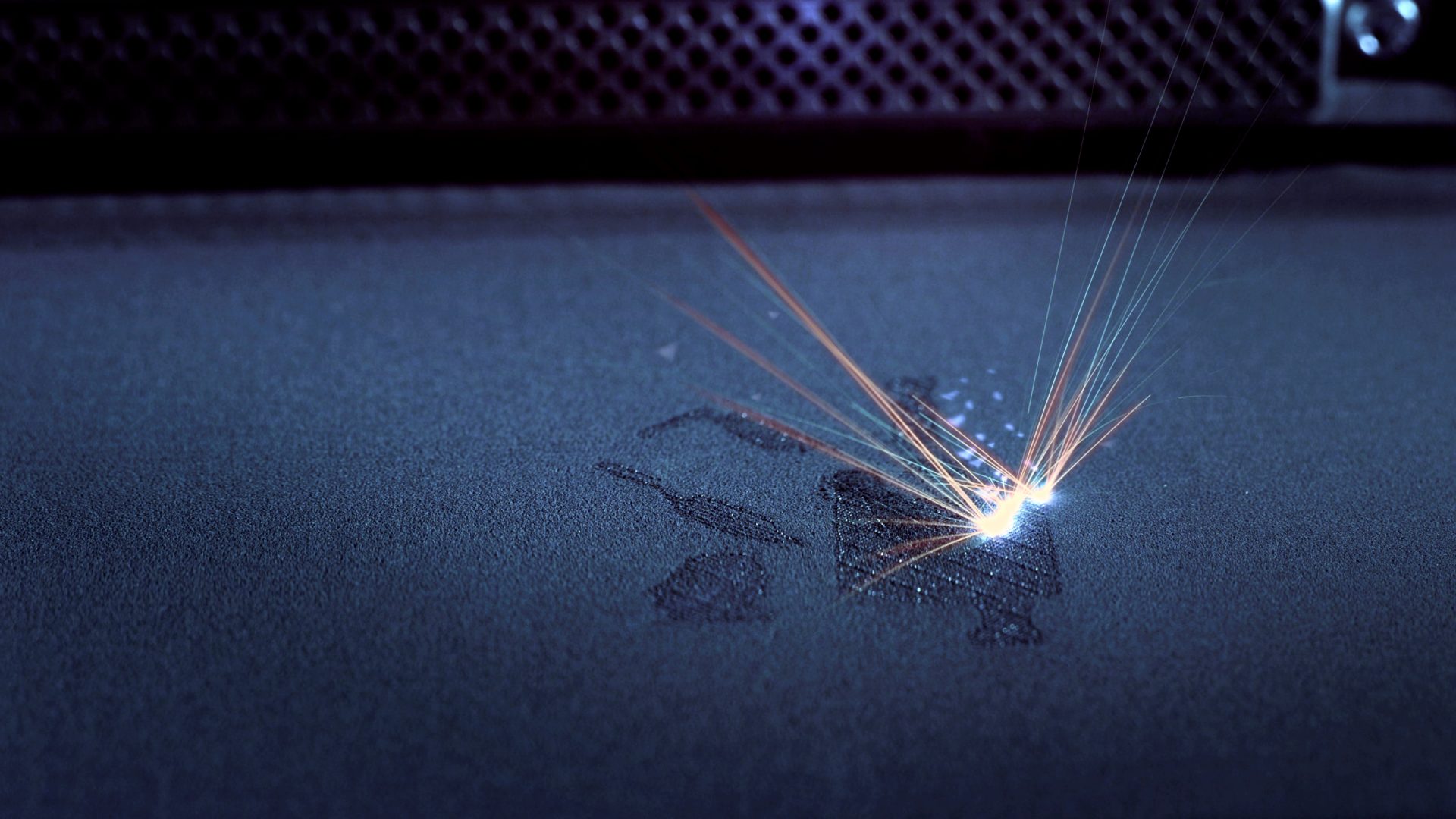

Direct Metal Laser Sintering – the process whereby successive layers of metal powder are fused together to form an object – is a subset of Additive Manufacturing techniques gaining favor in the rocket engine development community because of its ability to quickly and cost-effectively produce complex components. However, due to current part size “printing” limitations and the extreme material performance requirements, the value of this alternative manufacturing technique, as applied to turbomachinery, is not well understood by the industry as large. Now, thanks to funding from the Air Force, and a team including Barber-Nichols Inc. (BNI) and Northrop Grumman Aerospace Systems (NGC), with support from NASA- Marshall, that is soon to change.

The Air Force, as part of a larger effort to mature technologies desired to ease the transition of the United States away from dependence on Russian-made RD-180 engines, awarded the BNI/NGC team approximately $5.5M to Design and Additively Manufacture a Booster Class Turbo Pump for a 300,000lb thrust first stage booster engine using liquid oxygen (LOX) and liquid methane (LNG) propellants. Methane is a propellant of interest due to its high specific energy density, cost efficiency, and wide availability (including Mars). The team’s work is expanding and extending the ongoing research being conducted at NASA Marshall in Huntsville, Alabama where they recently designed, assembled, and successfully tested an additively manufactured turbopump set that would notionally power a 35,000lb thrust LOX / Liquid Hydrogen (LH2) engine.

A technology maturation program, the 2-year effort will ideally conclude with the US industry having an extended set of AM turbomachinery material design properties, a qualified set of design and vendors and vendor selection processes, and an assembled ground demonstration turbopump ready for testing.