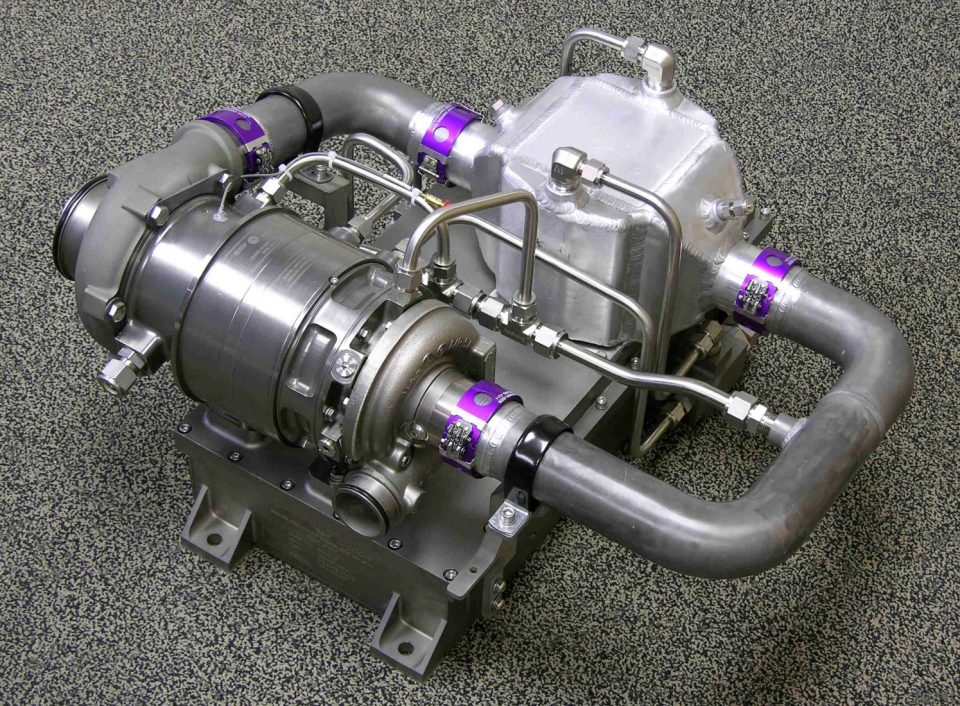

Barber-Nichols develops, analyzes, builds, and tests over 15 clean sheet designs on average, annually. Our rigorous design process ensures our customer’s most demanding requirements are met. BN’s real-world test-verified analysis tools quickly hone in on an optimized solution and identify technical risks early in the development cycle. Expensive and time-consuming late-cycle design iterations can be eliminated.

Engineering: Custom Design, Analysis, & Prototyping

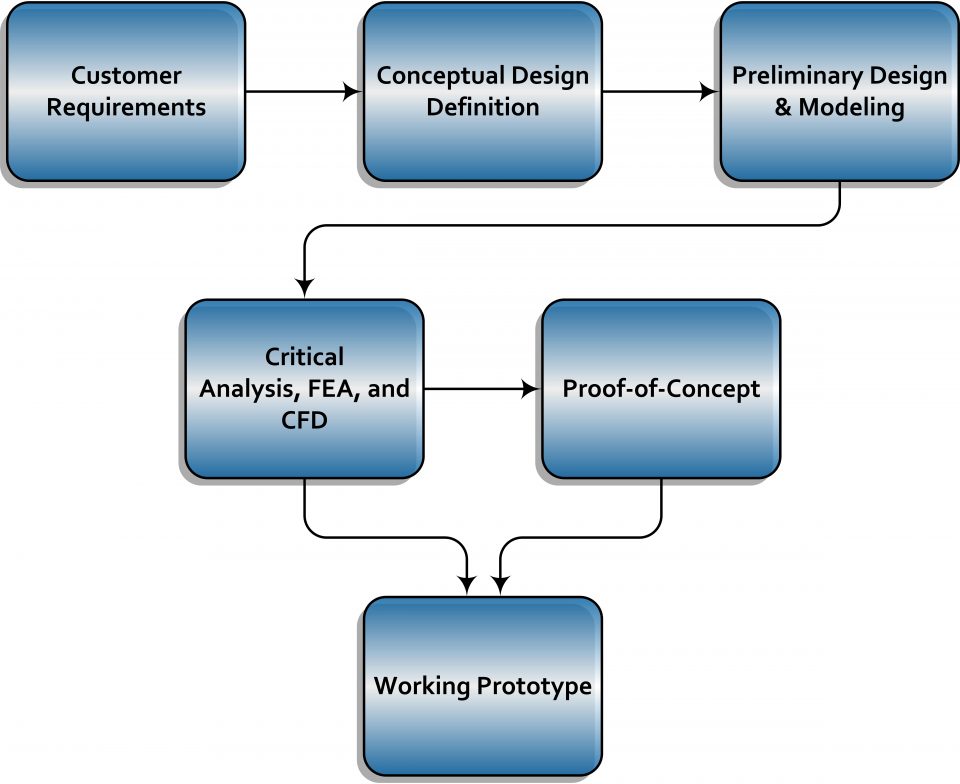

Barber-Nichols (BN) possesses the sophisticated tools and experienced personnel to take the most technical engineering challenges from concept to reality. The custom design process begins by understanding each individual customer’s requirements, using them to create a project specification, and defining the initial technical concept. Whether we are developing a custom component of a more extensive system, such as a pump, compressor, or turbine; or the entire system itself, clean-sheet designs follow a three-staged, gated development process, including Conceptual Design, Preliminary Design, and Critical Design phases. Each phase concludes with a detailed review of the current state to ensure it meets requirements before proceeding to the next stage.

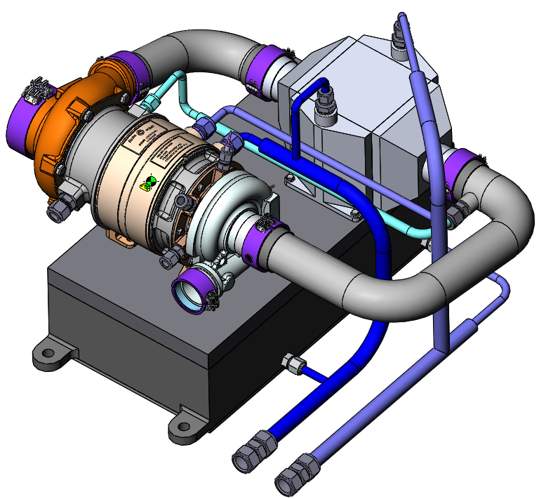

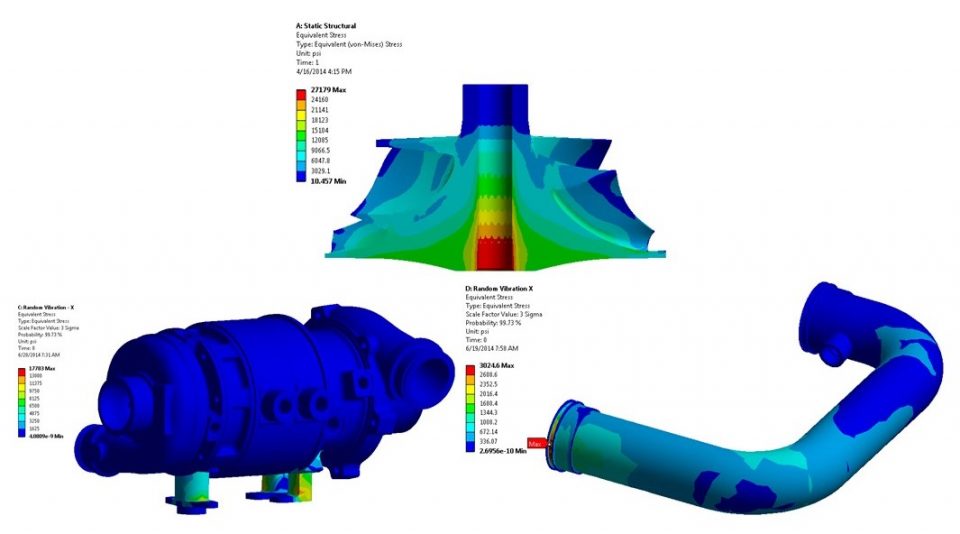

It is during this process that BN designers create initial 2D sketches that can be used to evaluate the feasibility and manufacturability of the configuration as it matures. These 2D sketches are used to create detailed 3D models which undergo various engineering analyses to review the design and establish a level of confidence that it will perform to operational requirements. Aerodynamic analyses can help to predict if rotating equipment will meet its stated performance requirements. Stress, thermal, and vibration models can help our engineers understand how a specific component or piece of equipment will react within its operating environment. before it can be considered ready for sign-off.This portion of the process can be highly iterative, and it is very common for parts or all of the design to be revised several times.

Engineering analyses involve the use of mathematical models, structural finite element analysis (FEA), aerodynamic and hydraulic computational fluid dynamics (CFD), as well as complex system-level simulation. To accomplish this, BN engineers use some of the most rigorous and trusted modeling tools the industry has to offer to establish the confidence needed prior to manufacturing.

3D Modeling & Drafting: SolidWorks

Aero & Fluid Dynamics: CFX, NASA, Barber-Nichols Proprietary

Stress, Thermal & Vibration Analysis: ANSYS

Rotordynamic & Bearing Analysis: XL-Rotor, XL- Bearing Suite

Motor Design: SPEED, MagneForce

Circuit Design: Spice, Quartus, Altium DXP

Full Physics System Modeling: Amesim, Matlab Simulink

BN engineers are developing clean sheet and derivative designs daily, many of which are required to pass various MIL-STD or DO-160G qualification tests prior to being placed in service. The detail and rigor of the design & development process ensure that the resulting equipment is of the highest quality, and able to meet the demands of each customer’s application the first time.