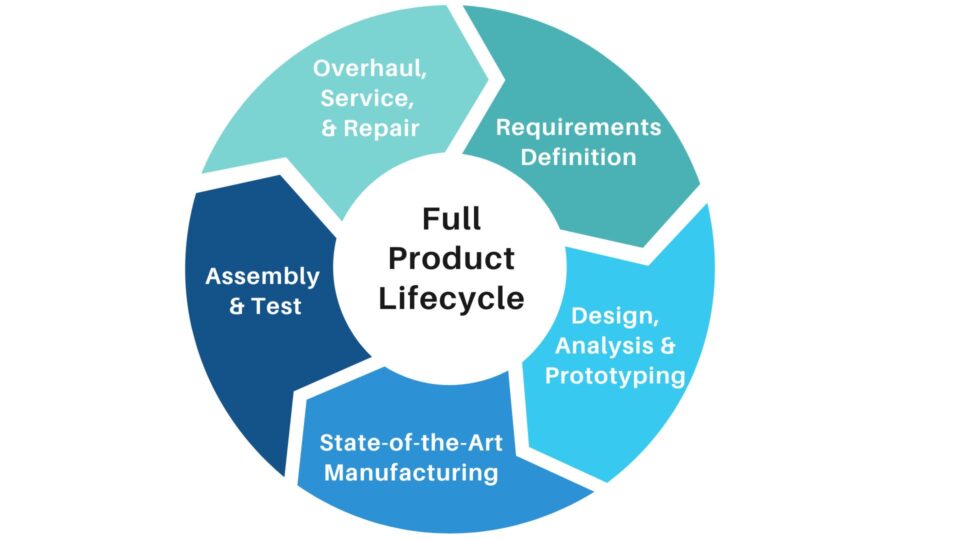

Barber-Nichols can support your Full Product Lifecycle from developing specifications and initial concept definition through aftermarket service and repair and everything in between.

- Requirements Definition & Management

- Engineering: Custom Design, Analysis, & Prototyping

- Advanced Manufacturing

- Assembly & Test

- Overhaul, Maintenance & Repair Services