In 2004 the U.S. Department of Energy (DOE) Office of Nuclear Energy and the Massachusetts Institute of Technology (MIT) theorized that replacing a traditional steam Rankine cycle in a power plant with a supercritical carbon dioxide (CO2) Brayton cycle would be 7% – 12% more efficient and allow power plants to deliver more electricity from a fixed amount of fuel. To further this research, the DOE tasked Sandia National Laboratories (SNL) with investigating supercritical CO2 power cycles and advancing its technical readiness level. This resulted in the identification of several technical risk items that needed to be addressed before the technology could advance to commercialization. A sub-scale supercritical CO2 power cycle test loop would have to be built to validate the efficiency theory and the four technical risk items of greatest concern were compressor performance and stability, heat exchanger performance, system start-up, and system controllability.

Recognizing that many of the technical risk items were directly related to turbomachinery and control, SNL partnered with Barber-Nichols Inc. (BNI) based on the company’s proven ability to manage turbomachinery development project and quickly modify prototype equipment based on test results. The project was split into two phases with initiation of the second phase dependent upon positive results in the first phase. Phase one’s objective was to confirm compressor performance and stability at CO2’s critical point which was the item of greatest technical risk. The results did prove positive and detailed information can be found in the Noall/Pasch paper entitled Achievable Efficiency and Stability of Supercritical CO2 Compressor Systems which was presented at the 2014 Supercritical CO2 Power Cycle Symposium.

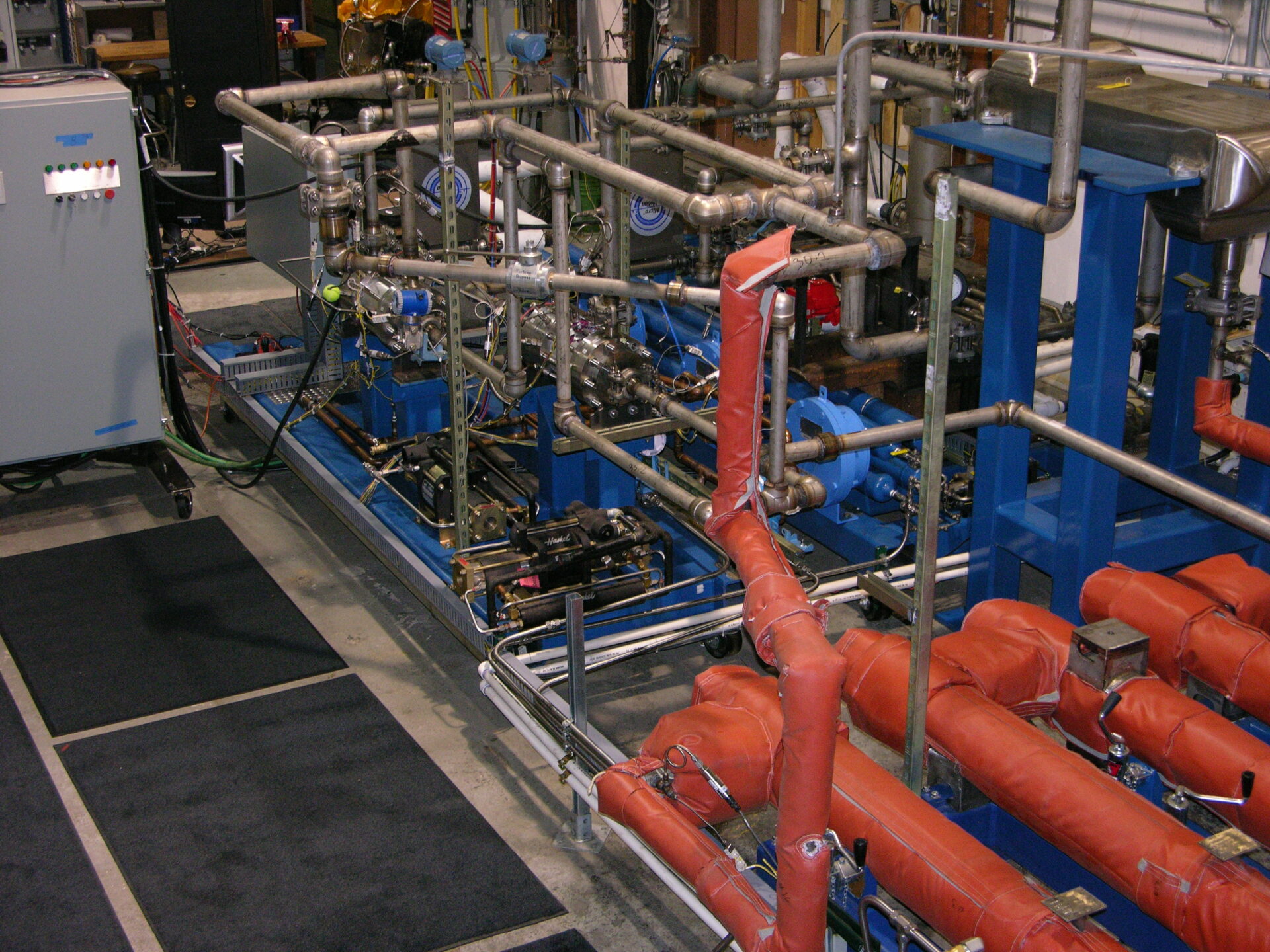

Subsequently, SNL and BNI moved on to phase-two and built the 300 kW test loop where high power density heat exchanger performance also proved positive and system start-up protocols and system controllability were established. Detailed information related to system start-up can be found in the Eisemann/Fuller paper entitled Supercritical CO2 Brayton Cycle Design and System Start-Up Options which was presented at the 2011 Supercritical CO2 Power Cycle Symposium.

Additionally, during phase two, BNI developed enabling technologies which included high-speed foil bearings and patented floating labyrinth seals for use with supercritical CO2 and a Combined Motor/Generator Controller that allowed the test loop’s turbo-compressor to seamlessly switch between motoring and generating on the fly. Most critically, the measured test loop efficiency was within 2% of predicted efficiency, validating the original theory developed by the DOE and MIT in 2004 that a full-scale supercritical CO2 power plant could attain 45% – 50% efficiency which is 7% – 12% more efficient than current steam cycle technology.