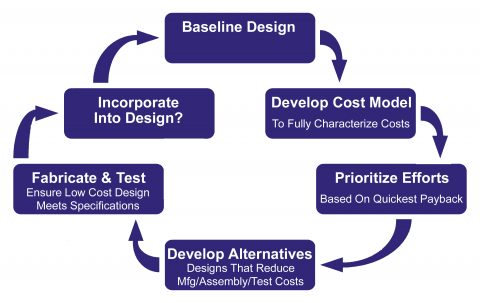

As BN is both an engineering and a manufacturing company, Design for Manufacture (DFM) is more than just a concept, it is a daily reality. BN has a strong corporate culture of open communication where engineering and manufacturing personnel exchange ideas directly in both formal and informal settings. Manufacturing personnel provides design input from the conceptual design phase through the release of detailed manufacturing drawings. BN also incorporates the concepts of Design for Assembly and Design for Cost into its DFM program. Research indicates that 75% of a product’s cost is established during the design process.

BN has equally talented engineering and manufacturing teams co-located in a single campus. Manufacturing input is integrated into all designs from the conceptual phase to ensure each component and assembly is economically manufacturable. A regimented process is followed to ensure that manufacturability is balanced with robustness to meet the most stringent customer requirements.