Barber Nichols is excited to share our recent advancements in developing and applying predictive models for cryogenic induction motor performance. These new capabilities significantly benefit cryogenic turbomachinery in industries like energy and beyond.

- Sparse Materials Data: Designing induction motors that can operate reliably in cryogenic conditions can be challenging due to the scarcity of material properties data available under these extreme temperatures. This highlights the importance of having accurate predictive models to compensate for the lack of empirical data.

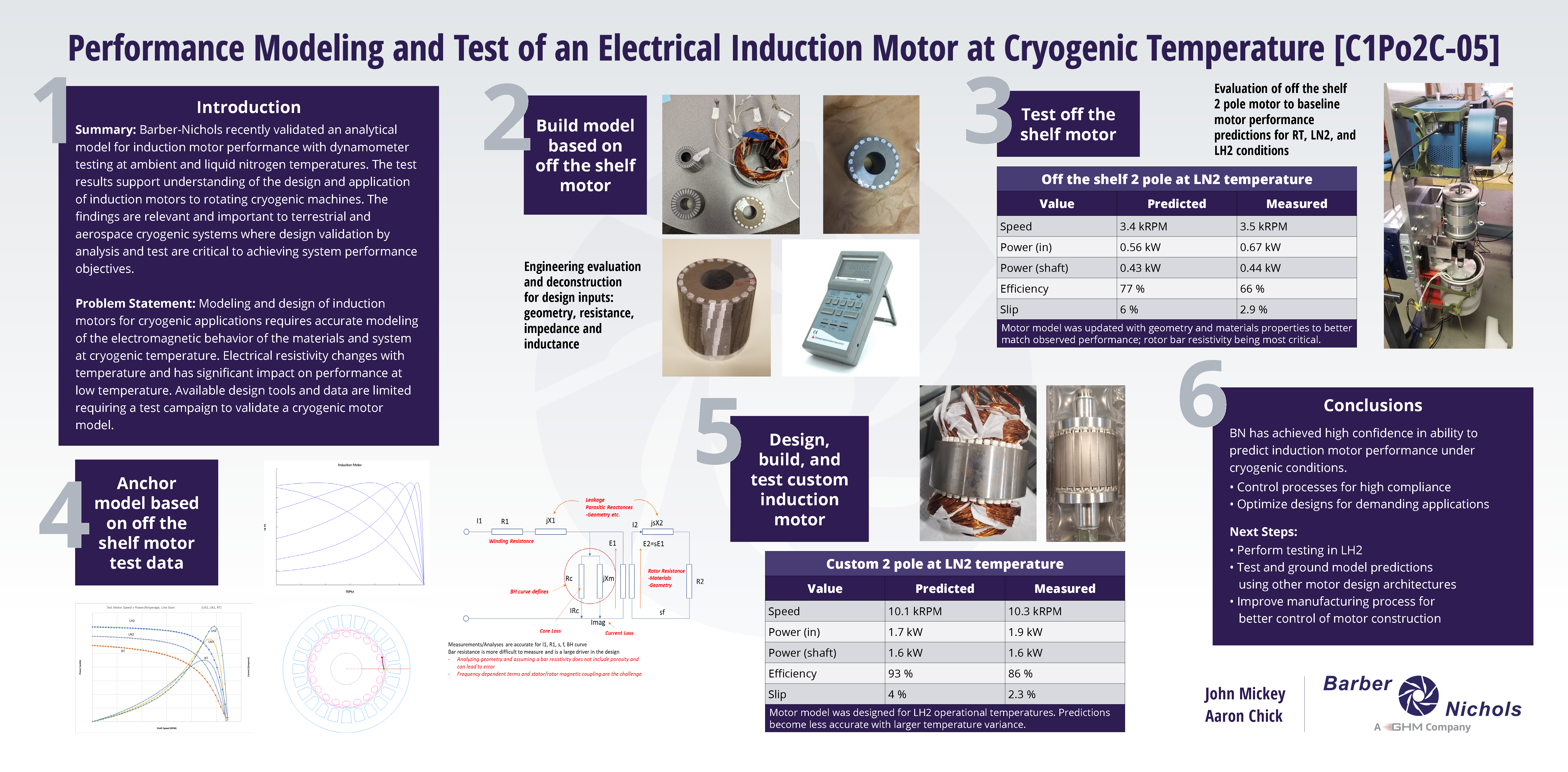

- Iterative Model Development: Barber Nichols used an iterative approach, leveraging test data to refine and improve the model assumptions. This iterative process contributed to the development of a more accurate model.

- Validation of Analytical Model: Barber Nichols successfully validated the model’s accuracy for predicting the performance of induction motors under cryogenic conditions via test. This is a significant achievement, providing a valuable tool for designing and optimizing such motors.

- Initial Use Case: The first practical application of this new tool was in designing a custom induction motor for an aerospace mission-critical liquid hydrogen circulation pump. The ability to validate a motor design capable of operating in such harsh environments suggests that the resulting technology has countless other applications in critical areas of cryogenic fluid management across aerospace and other industries alike.

- Current Evaluation and Future Integration: The custom induction motor is undergoing further evaluation on the same dynamometer rig used for model validation. Subsequently, it will be integrated with the pump assembly and operated in a hydrogen test loop later in the year, to undergo a comprehensive testing and validation process.

Contributing Authors: John Mickey, Barber-Nichols Lead Engineer – Motors and Aaron Chick, Senior Sales Engineer