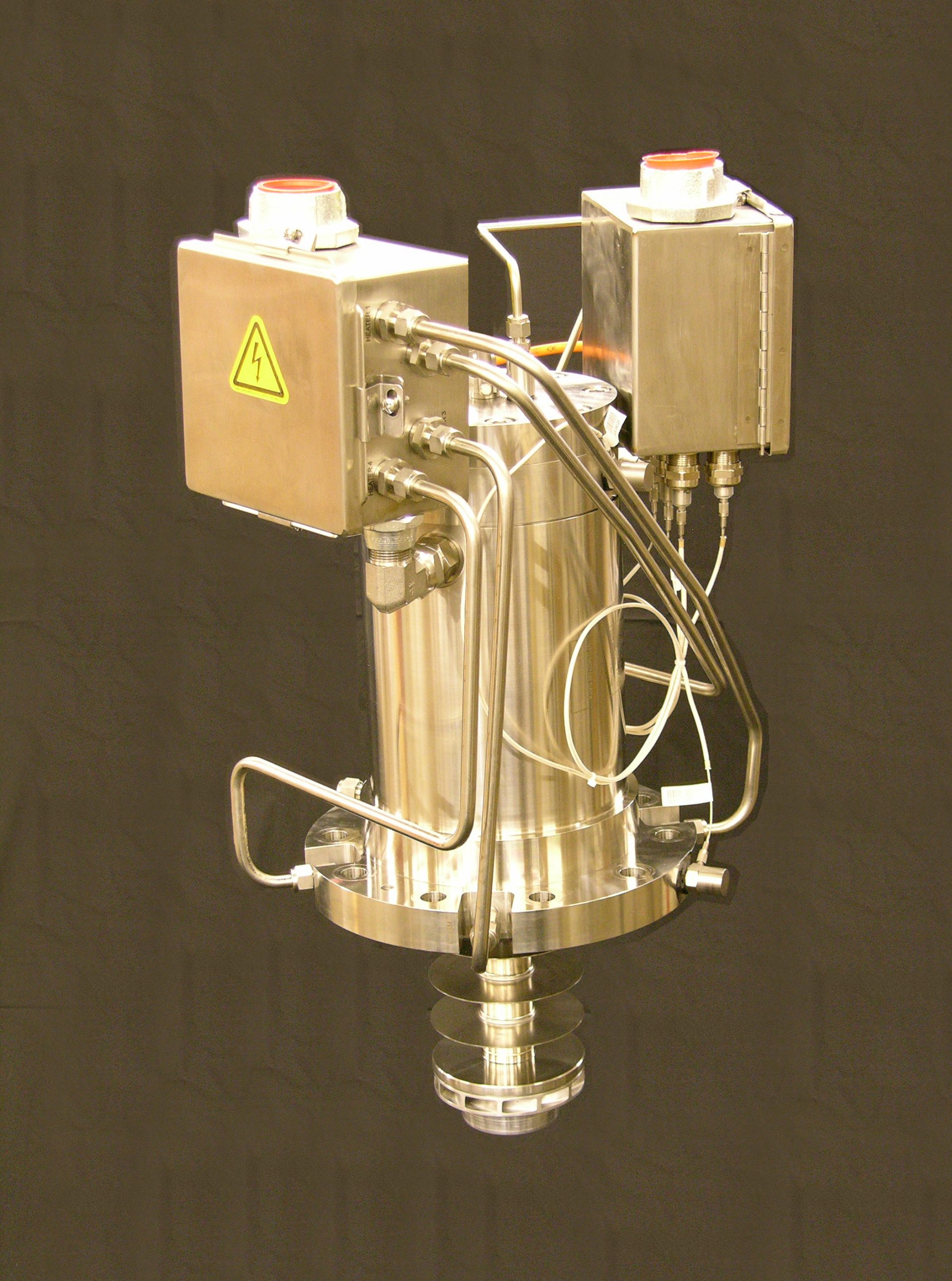

Barber-Nichols Inc. (BNI) is pleased to have been selected by ITER-India to supply the first supercritical helium circulation pump (i.e. the toroidal field magnet circulator) for the ITER nuclear fusion energy project. The pump will circulate supercritical helium at 4.5 Kelvin, or -269º Celsius, which will cool the superconducting toroidal field magnets in the tokamak fusion reactor.

The ITER nuclear fusion energy project is designed to produce 500 megawatts of power. It is under construction near the Cadarache facility in southern France and is being built and operated by seven-member partners; the European Union, India, Japan, China, Russia, South Korea, and the United States. Nuclear fusion is the reaction that takes place in the sun where hydrogen atoms are fused together to produce helium and energy. On earth, this reaction promises abundant energy free from atmospheric pollutants and radioactive waste with an extremely short life compared with waste from conventional nuclear fission reactions. And as global populations continue to grow and developing economies become more affluent, energy security will continue to increase in importance.

The ITER project seeks to start the fusion reaction with hydrogen isotopes heated to 150 Million degrees Celsius which is ten times hotter than the center of the sun. At this temperature, a hot electrically charged gas called plasma will be produced where the hydrogen isotopes are fused together to produce helium, neutrons, and energy. And because the super-heated plasma will melt any material it touches, it will be contained using a magnetic field. The magnetic containment field will be produced using superconducting magnets which are forced cooled with supercritical helium.

According to the ITER Joint Implementation Agreement (JIA), the seven-member partners will share the construction costs for the project with each member partner producing critical systems to be delivered to the construction site. ITER-India is producing the following critical systems and the supercritical helium circulation pump being supplied by Barber-Nichols will be incorporated into the cryo-distribution system subject to successful qualification testing.

- Cryostat and Vacuum Vessel Pressure Suppression System (VVPSS)

- Vacuum Vessel In-Wall Shields

- Cryoline and Cryo-Distribution System

- Cooling Water System

- Ion Cyclotron Resonance Heating (ICRH) Sources

- Startup Electron Cyclotron Resonance System (ECRH) Sources

- Diagnostic Neutral Beam

- Diagnostic Systems

- Regulated High Voltage Power Supplies

Barber-Nichols has 40 years of experience with cryogenic pumps and systems and is pleased to be a part of this project. In 1974, BNI designed and built its first cryogenic pump for the National Bureau of Standards (now the National Institute of Standards and Technology). The liquid helium pump exceeded NIST’s expectations and since that time Barber-Nichols’ reputation as an international manufacturer of custom cryogenic circulators, compressors, and pumps has flourished. More recently BNI designed and built one of the world’s largest liquid helium pumps to cool superconducting magnets in CERN’s ATLAS Detector. Barber-Nichols’ cryogenic hardware is hermetically sealed and minimizes heat leak which are both crucial for cryogenic applications. BNI’s cryogenic circulators, compressors, and pumps are currently being used around the world for:

- The circulation of argon (87 K [-303 °F]) for particle research.

- The circulation of nitrogen (77 K [-321 °F]) for the cooling of high-temperature superconducting magnets & synchrotron beamline crystals.

- The circulation of supercritical helium (4.2 K [-452 °F]) for the cooling of superconducting magnets.

- The circulation of liquid neon, krypton, xenon, and more.