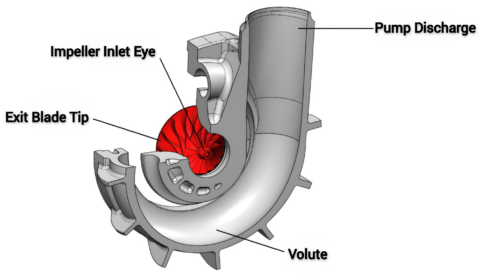

Centrifugal pumps use a rotating impeller to impart kinetic energy into a working fluid by accelerating it radially outward. As the high-velocity fluid exits the tip of the impeller blades it is routed into the pump volute or diffuser, each of which has an increasing cross-sectional area, where the velocity of the fluid slows causing an increase in pressure head in the fluid. High-speed centrifugal pumps are particularly effective, as pump Affinity Laws show how an increase in the operating speed of the pump causes an exponential increase in the pressure head developed.

High-speed centrifugal pumps can be very compact and because they have fewer moving parts compared to other high-pressure pump technology, they are often an ideal choice for applications where size, weight, and reliability matter.

Barber-Nichols’ reputation is built upon the capability and willingness to develop specialty pump solutions that meet the specific needs of customers. The products detailed below provide a representative sample of some of the most popular configurations, while our team of engineers continue to create new pump designs daily, that draw upon knowledge gained over more than 50 years as a business.