First, it is extremely difficult, and sometimes impossible, to prevent mechanical seals from leaking in a cryogenic environment. Therefore, BN’s hermetically designed pumps completely eliminate mechanical seals and thereby eliminate this problem. Second, thin-walled pump shafts, thin-walled shaft housings, and anti-convection/radiation heat shields all work together to minimize conductive and convective motor heat leaking into the cryogenic fluid. Third, Barber-Nichols’ extensive experience with unique, high-speed bearings allows it to design pumps that can operate at suitably high speeds for long periods of time between scheduled maintenance. Operating a pump at a higher speed increases the pump’s hydraulic efficiency further minimizing the heating of the process fluid. Finally, BN pioneered the development of cryogenic pumps with vacuum housings. This allows maintenance personnel to remove the pump from a cryostat without breaking the cold box vacuum.

Cryogenic Pumps

Barber-Nichols' Cryogenic Pumps Are Highly Beneficial For Four Reasons

Submersible Motor Pumps

Submerged motor cryogenic pumps are commonly used when heat leak during operation is not a primary concern, or when intermittent pump operation is expected. Because the motor is submerged, operating inefficiency will be imparted into the fluid in the form of heat. However, because the motor is mounted inside the vessel, there is no conductive heat path from the outside when the pump is turned off for prolonged periods.

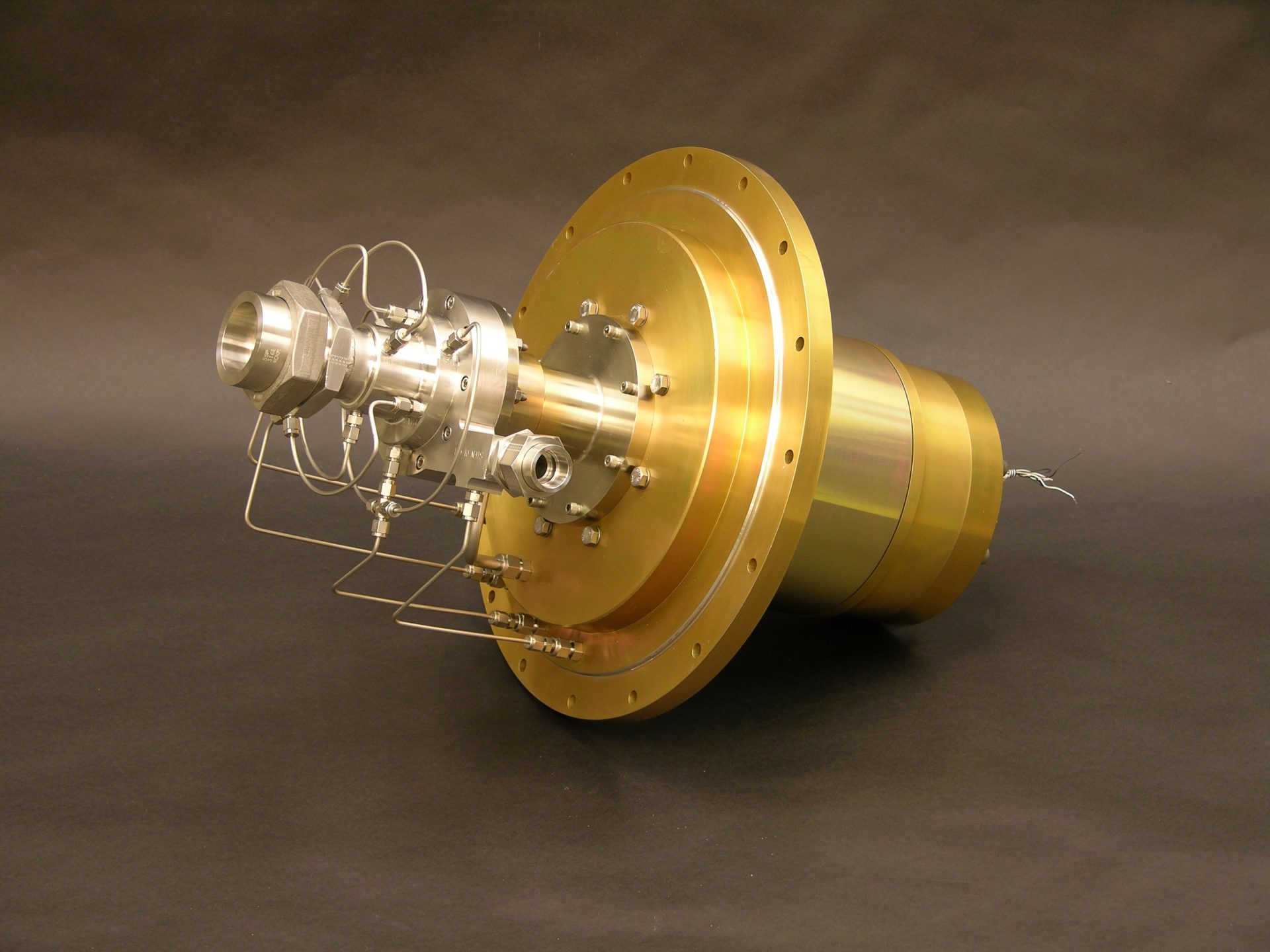

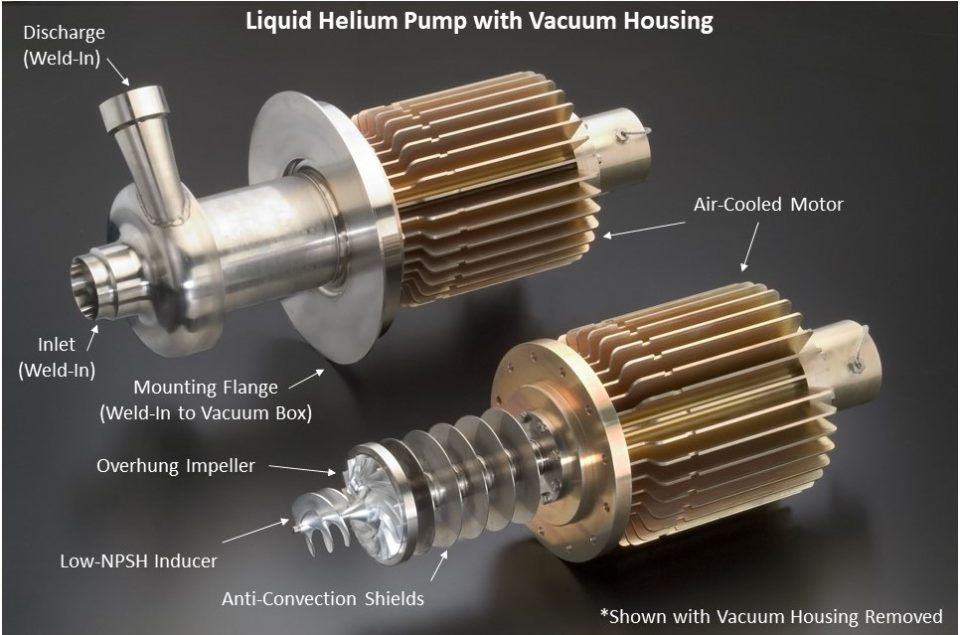

Vacuum Housing Pumps

Vacuum housing pumps aim to reduce heat leak by creating a barrier between the motor and the cryogenic fluid. Barber Nichols’ vacuum housing pumps also utilize anti-convective heat shields to create additional resistance and further limit heat transfer. These pumps are commonly welded into the top plate of a dewar, an insulated vessel specifically designed to store cryogenic liquids.

Long-Shaft Pumps

Long-shaft pumps have a pump housing and impeller that is submerged in the cryogenic fluid, which is separated from the motor by an extended driveshaft. The driveshaft is hollow to reduce the conductive heat path, and it is surrounded by a stationary tube to provide structural support. Specialized bearings are used to support the driveshaft rotordynamically, while providing acceptable operating life in a cryogenic environment.

Below are more in-depth pages covering the most common cryogenic fluids:

Liquid Helium Pumps

Liquid Hydrogen Pumps

Liquid Nitrogen Pumps

Liquid Oxygen Pumps

Low-Pressure LNG Fuel Pumps