Barber-Nichols Inc. (BNI) designs and produces prototype Supercritical Carbon Dioxide (CO2) Pumps. Supercritical CO2 is an excellent solvent, and therefore extremely effective for the cleaning of textiles and electronic components. Because Supercritical CO2 systems operate at high pressure, BNI’s hermetically sealed pumps are an excellent choice for this application.

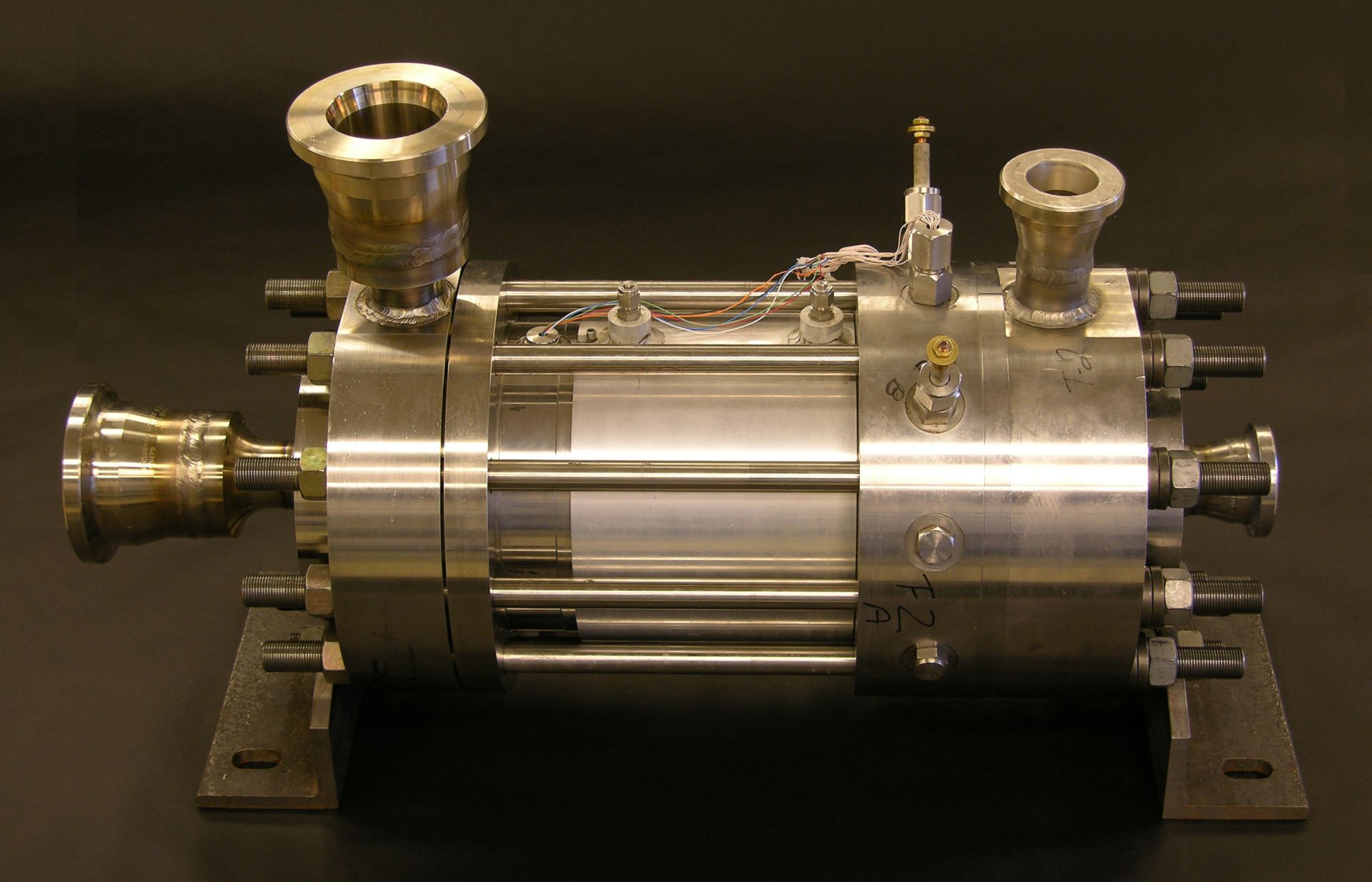

Barber-Nichols designed and produced Supercritical CO2 Pumps for two dry cleaning system manufacturers. The most common dry cleaning fluid in the United States today is a hazardous substance called Perchloroethylene (PERC). These two new environmentally-friendly systems use Supercritical CO2, rather than PERC, and require BNI’s circulation pumps for operation. The pumps are hermetically sealed to prevent carbon dioxide from escaping the high-pressure system, and utilize Supercritical CO2 for cooling and lubrication. BNI’s work with low lubricity toluene lubricated bearings in the 1980s and water-lubricated bearings in the 1990s uniquely positioned the company for these projects.

Barber-Nichols also helped customers with the use of Supercritical CO2 in an alternative textile dyeing process. Currently, the dye is dissolved in water and then applied to textiles. The process renders large quantities of water that must be cleaned before it can be reused or released from a factory. If the dye is dissolved in Supercritical CO2 rather than in water, the cleanup process is simplified. The Supercritical CO2 is depressurized at the end of the process, the dye drops out of solution, and the gaseous CO2 and dye are easily separated.