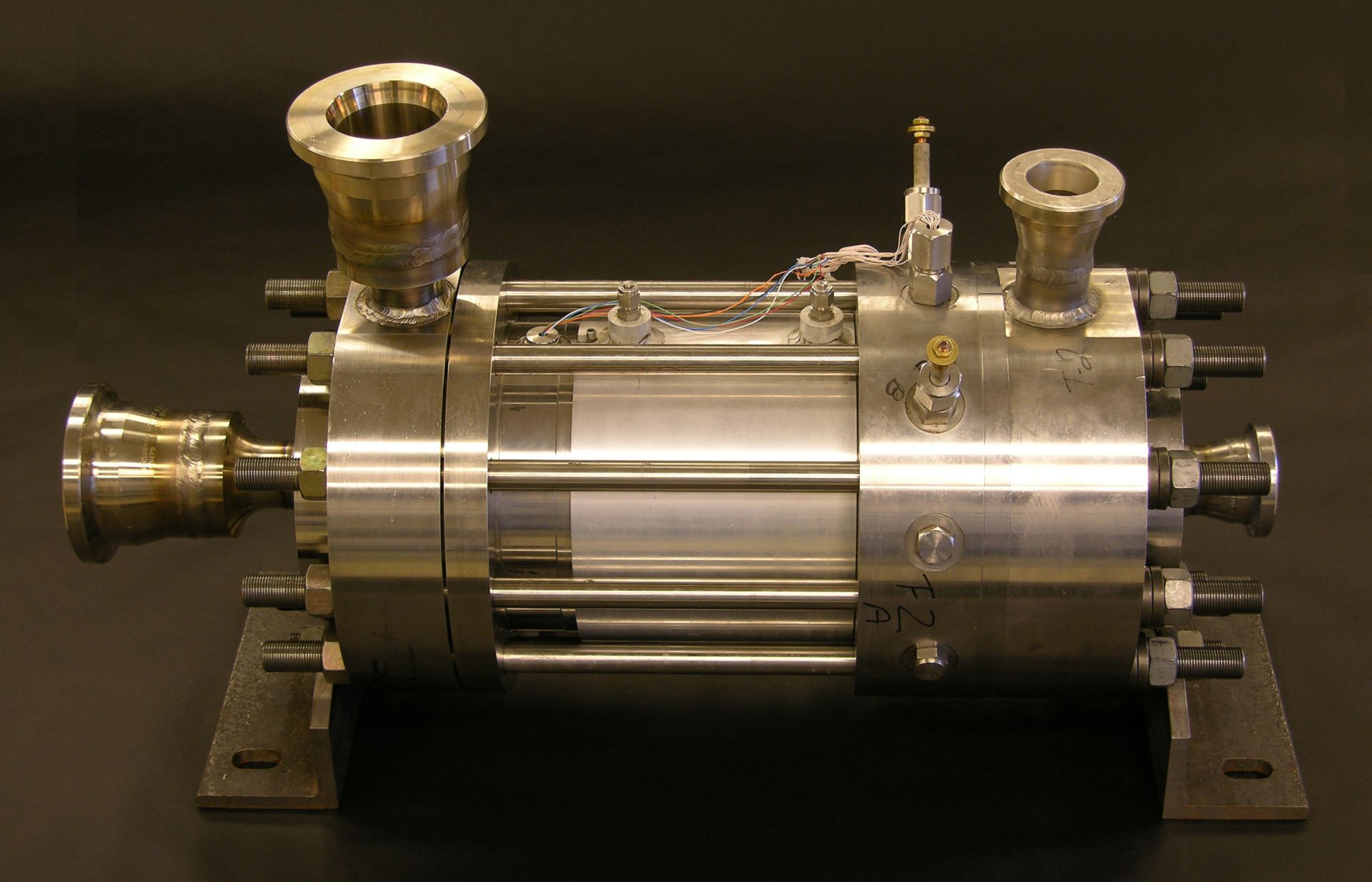

BN offers radial in-flow and axial designs (including two-stage) for unique process applications, up to 10 MW in capacity. Typical applications are Organic Rankine Cycle or Brayton Cycle power turbines, handling hydrocarbons, refrigerants, or CO2 as working fluids. Other heritage applications include process letdown expanders for air or nitrogen. Material offerings include nodular iron, steel, stainless steel, and Inconel for high-temperature duties. Sealing options include dual seals with the working fluid, bearing lubricant, or other fluids acting as the seal buffer. Bearing options include rolling element, fluid film, or hydrostatic. Discharge mating pipes with integral diffusers are typically included to ensure the highest efficiency.

BN offers turbines as one-off products for unique project applications or custom turbine product families designed for OEMs of packaged power systems. BN can offer a fully skidded unit with a turbine, speed-reducing gearbox, generator, lube systems, and PLC-based instrumentation monitoring and control system. Also common is the supply of the turbine as a single module directly to the OEM for skidding by their operation. Either way, you get the performance benefit of a custom-engineered turbine and can use as much or as little of BN’s experience as desired to ensure a trouble-free installation and commissioning.

Barber-Nichols has the infrastructure to support the sale, installation, and maintenance of Turbine-Generators in North America only.