Bearing Problems We Solve

Problem 1: Design a foil bearing for specific operating environment

What was the solution? Xdot has collaborated with multiple clients to determine the specific needs for new foil bearings, to develop custom state-of-the-art foil bearings, and to support bearing integration and machine development.

Xdot has successfully partnered with these types of customers to develop foil bearings to meet a range of requirements:

- Aerospace customer building a gas turbine that needed to operate in a hot environment (up to 1200 F / 650 C). Xdot can also support development for very cold environments (down to cryogenic temperatures).

- Customer in the consumer space with a product that required a long life at very high shaft surface speeds.

- Customers at a national lab and in the commercial distributed power industry who needed to use the process gas to eliminate oil and oil systems (Air, Refrigerants, Supercritical Carbon Dioxide, etc.).

- Aerospace DoD application to enable compact, lightweight systems.

We go beyond just developing a product and leaving it up to our customers to integrate into their systems. Our services include answering your design, assembly, integration, and testing questions. We continue to support you after product delivery, with consulting about interpreting test data. For interested customers, we can also support your own in-house development and production when your team is ready.

Problem 2: Validate new bearing designs

What was the customer’s key problem? An oil and gas industry customer wanted initial validation of new bearing designs as a component.

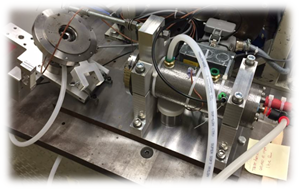

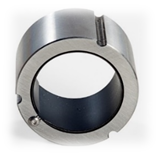

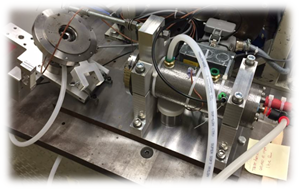

What was Xdot’s solution? Like many of our customers, this company lacked the in-house capability to fully evaluate new bearing designs. For this client, Xdot provided analysis and subscale testing of large, polymer lined, water lubricated bearings to maximize bearing reliability.

Xdot brought our extensive foil bearing test experience to advise the customer on best practices for testing and to develop a thorough analysis plan. We used our own cutting-edge high-speed bearing test facilities to evaluate the customer’s new bearing design. We were able to offer guidance for next steps based on the test results and our own expertise about bearing design.

Depending on customer needs, Xdot can produce new test rigs for testing in our Charlottesville facility or deliver custom bearing test rigs to customers.

Problem 3: Develop new foil bearing turbomachine

What was the customer’s key problem? A customer wanted to develop a new foil bearing turbomachine for a commercial application but needed a partner to bring the foil bearing expertise.

What was Xdot’s solution? In this case, Xdot was able to provide initial custom training about foil bearings and rotordynamics as well as follow up collaboration and support for the client’s in-house team as they worked to develop a new foil bearing turbomachine. With Xdot’s support, the customer was able to successfully identify performance requirements and begin development of a new foil bearing turbomachine.

Xdot can adapt our products and processes to provide prototype bearings, expertise in developing foil bearing machines, or training about foil bearings and rotordynamics.

Problem 4: Ensure bearing and equipment reliability

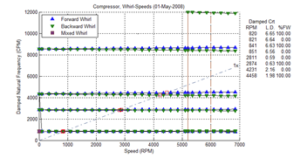

What is the key problem? Various customers needed a rotordynamics consultant to ensure equipment reliability and prevent “shake and break.”

Problem 5: Demonstrate proof of concept

What is the key problem? Multiple customers have needed a proof of concept demonstration and investigatory tests of bearing systems.

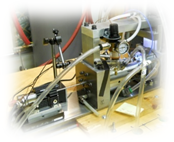

What was the solution? To assist these clients, Xdot has leveraged our in-house test rigs to rapidly test new bearing concepts. We have been able to assist our customers in evaluating their concepts before they committed funds and personnel to a significant in-house effort.

We have partnered with an aerospace customer to test a new high-speed ball bearing assembly, a process machinery developer to evaluate magnetic backup bearings, and an aerospace customer to validate performance of a foil bearing they’d developed.