Barber-Nichols engineers, manufactures, and tests thermal control pumps for extended-life missions. Using our turbomachinery heritage, we provide existing pump solutions, pump derivatives, or custom pumps to meet tailored system requirements.

Satellite Thermal Control Pumps

Features

- Typical mission life of 15 years, continuous

- Active thermal management via PD and centrifugal pumps

- Variety of working fluids: Ammonia, DI Water, EGW, Novec HFE 7200, PGW, Therminol D-12, and others

- Working fluid material compatibility assurance

- Hermetic design

- Permanent Magnet (PM) or Induction Motor Motor cooling via working fluid secondary flow

- Motor temperature monitoring (optional)

- Motor position sensing (optional)

- Power dense, high-efficiency design

- Start/stop capable

- Existing pump designs, pump derivatives, or custom pumps

- Clean room assembly

Heritage

- Flight-qualified pump in MEO satellite application (TRL-9)

- Flight-qualified for LEO and terrestrial (TRL-6)

Typical Acceptance Test Criteria

- Multiple Thermal Cycle Tests (ambient, low, & high)

- Flow and power at design points

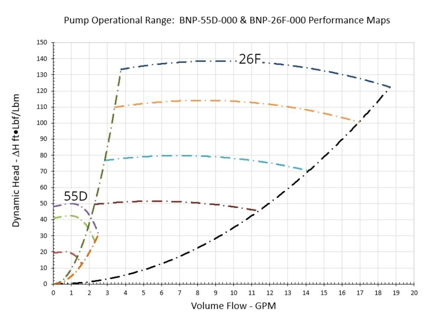

- Full performance map

- Flow rate operating range & system fluid resistance at design points

- Flow and power at design points

- Vibration Test

- Commutation Test

- Non-operating Tests

- External leakage at MEOP

- Winding insulation resistance test

- Thermistor functional test

- Connector receptacle termination resistance test

- Conductive material grounding test