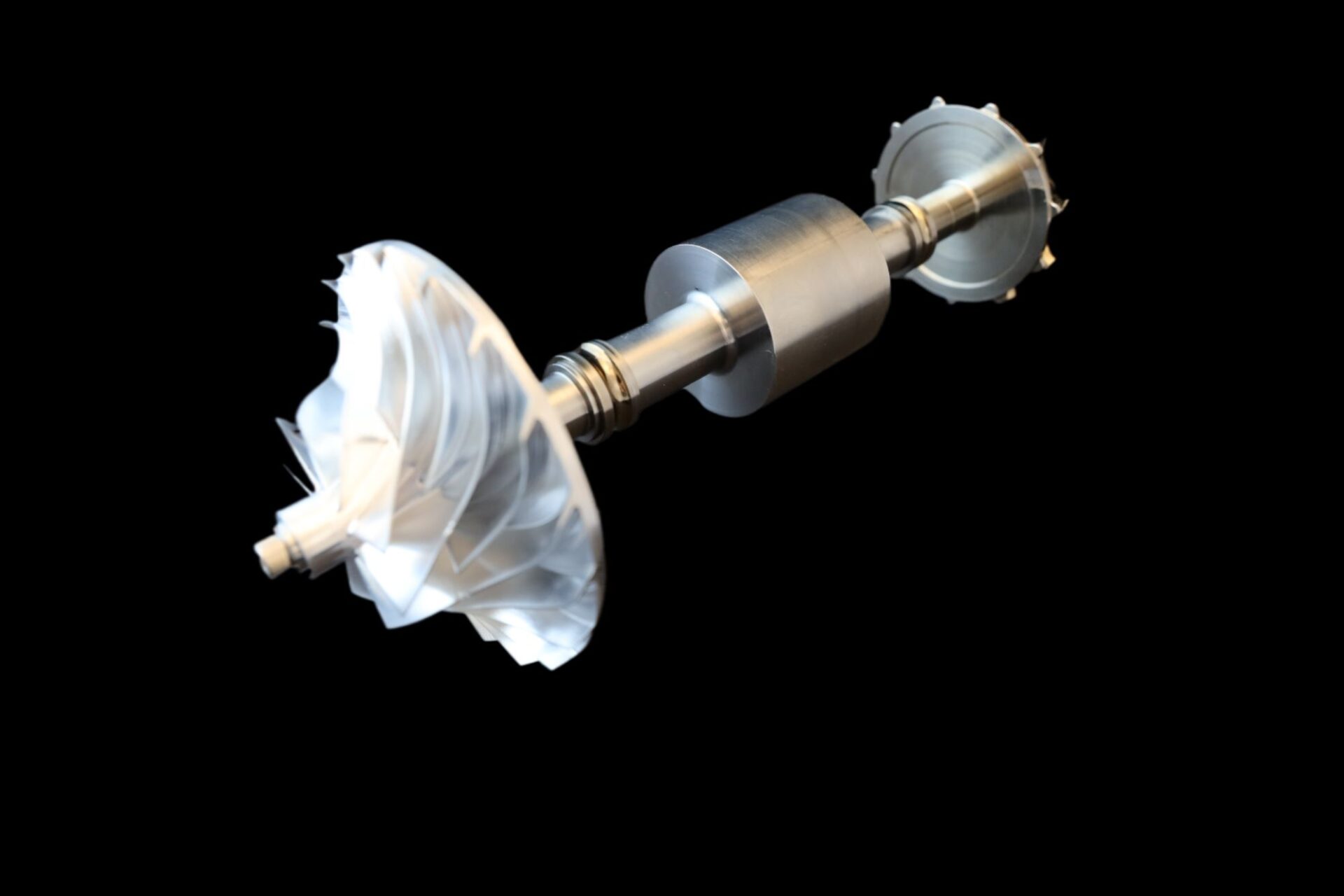

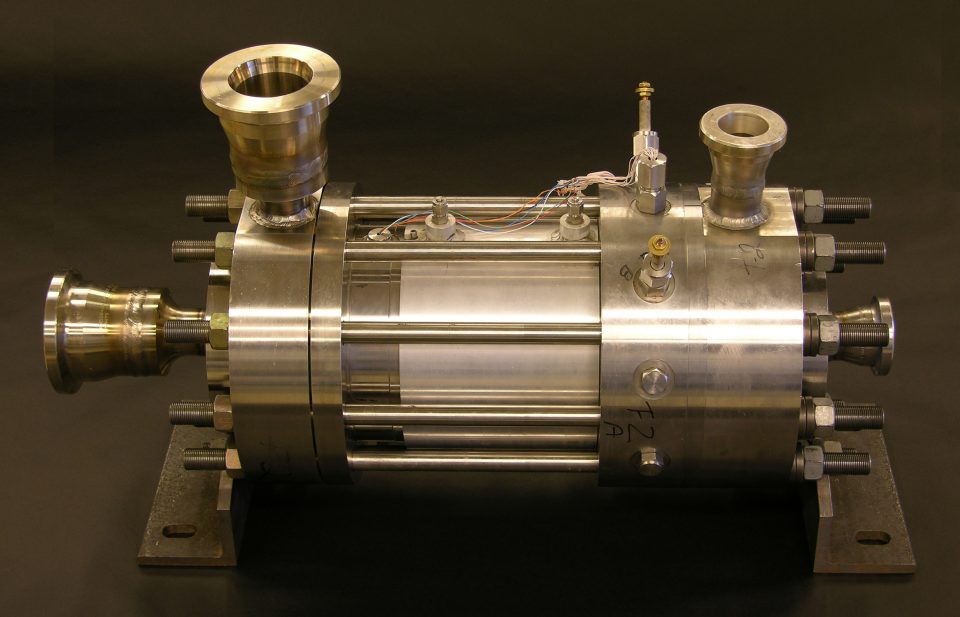

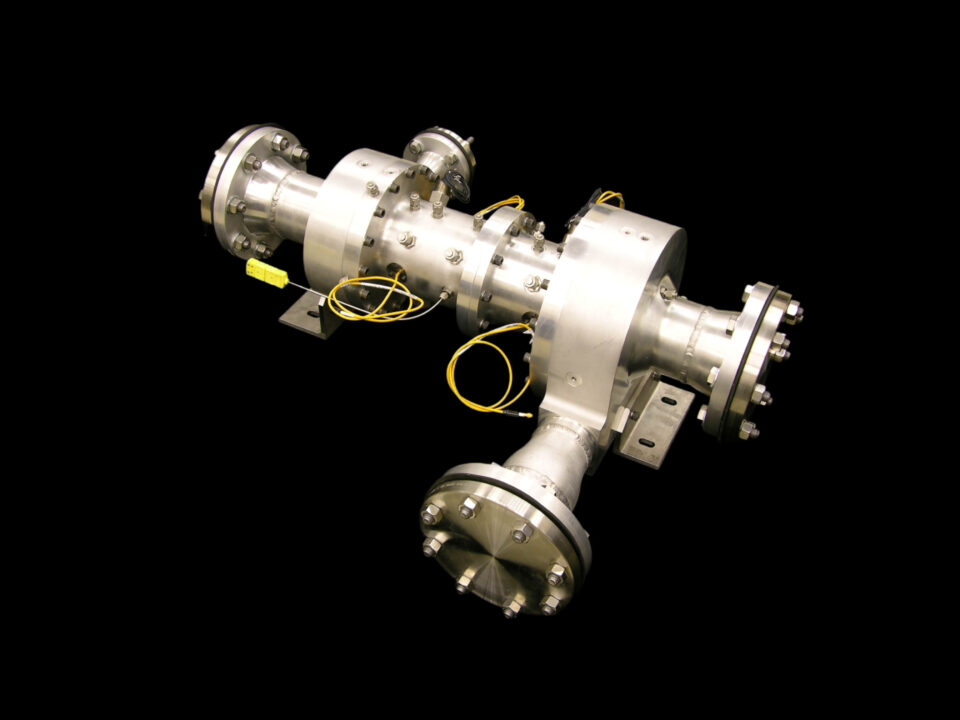

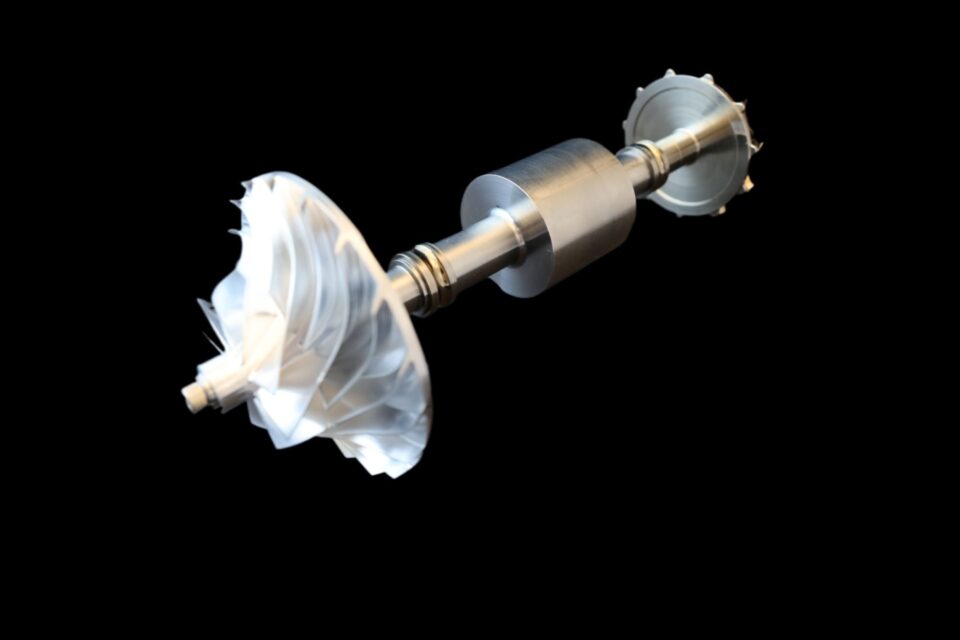

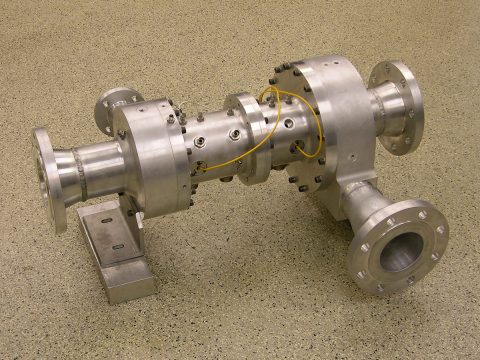

Barber-Nichols (BN) designs and manufactures high-performance turbocompressors for a range of industries, including energy and process applications. BN’s expertise spans turbine-compressor-generator assemblies for gas turbine engines and advanced turbocompressors for demanding industrial applications. Depending on the requirements, BN can economically modify automotive turbochargers or develop custom, clean-sheet designs for more complex needs.

Examples of customized products designed for specific customer applications: