Why Choose Barber-Nichols?

We don’t just print “best-effort” parts – we design, analyze, and optimize to print parts that meet your requirements, offering:

- Comprehensive understanding of application requirements

- Informed selection of candidate components for additive manufacturing

- Help build your business case comparing conventional 5-axis milling vs. investment casting vs. 3D printing

- Exhaustive material property database of additively manufactured materials with results from over 1,000 samples, including high-temperature, fatigue, and creep behavior of:

- Inconel 718

- Inconel 625

- Haynes 282

- 316 Stainless Steel

- 17-4 Stainless Steel

- Monel K500

- AlSi10Mg

- Full structural, thermal, electromagnetic, and CFD analysis

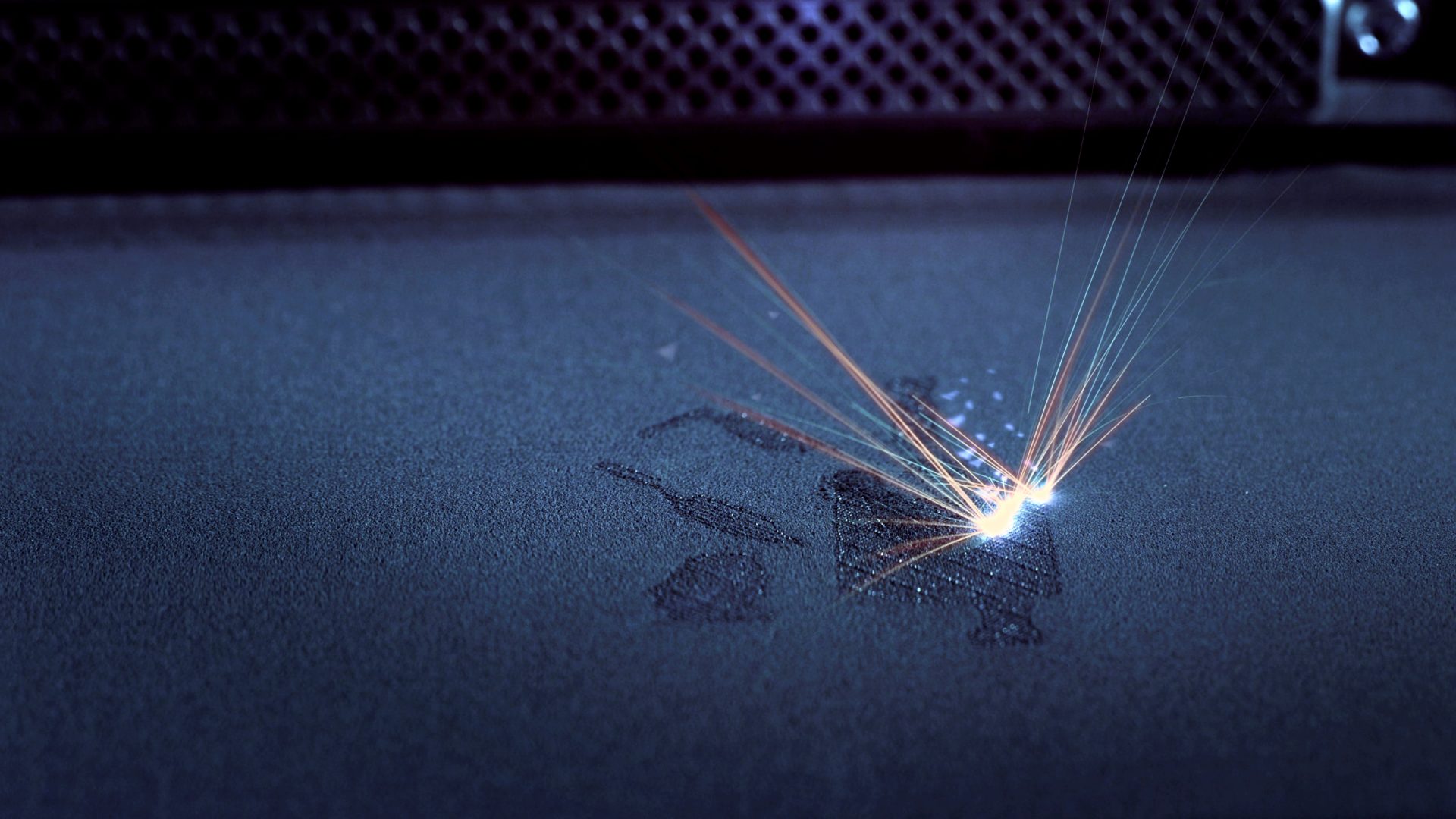

- In-house DMLS additive manufacturing capacity and parameter development

- World-class machine shop and advanced electrochemical machining (ECM) and polishing