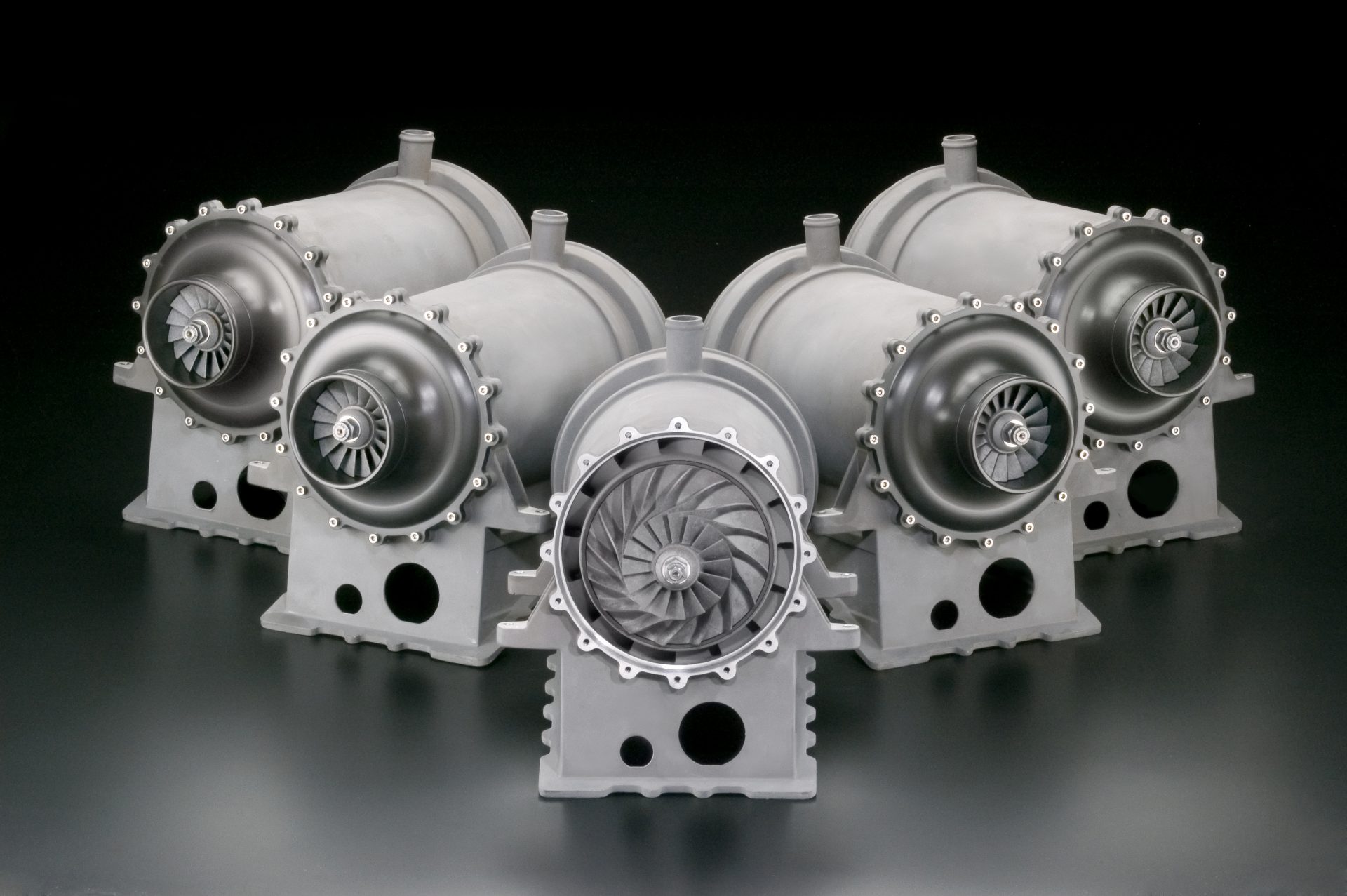

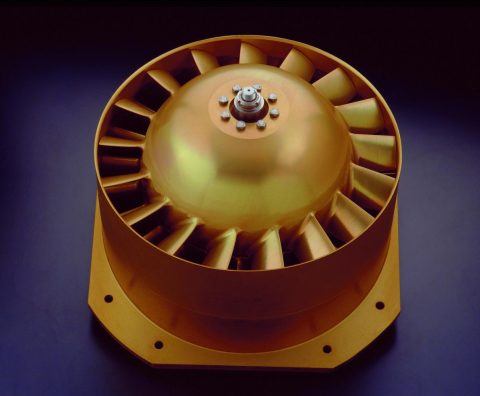

Barber-Nichols (BN) can provide a variety of pre-existing, specialty, and prototype military vehicle fans. Military vehicles of the future are becoming lighter, smaller, faster, and more power-dense. Improvements in vehicle survivability and reliability are also being made. As a result, the vehicle’s individual components must also be smaller, lighter, more efficient, and more robust. As propulsion power densities are being increased and hybrid drive systems are utilized, reliable cooling systems are paramount.

Barber-Nichols designed and produced the prototype Engine Compartment Cooling Fan for the Crusader 155mm Self-Propelled Howitzer. It is a single-stage axial-flow fan, driven by a brushless DC motor, and it has a variable speed drive to maintain efficiency. This 84 horsepower fan weighs 77 kg (170 lbs), produces discharge pressure at 61 cm (24 in) of water, and a volumetric flow rate of 23,786 m3/hr (14,000 ACFM). BN can design prototypes or modify existing military vehicle fans to accommodate a wide variety of applications including, but not limited to: electronics cooling, engine cooling, environmental control, life support, nuclear, biological, and chemical (NBC) systems, process gas transfer, and weapon system cooling.

Fans are conceptually designed using Meanline and streamline software. BladeGen® is then used to generate the three-dimensional blading and CFD Analysis is used to optimize the blade design for fan performance and noise reduction. BN utilizes Stereolithography (SLA) generated investment castings and/or five-axis machining to rapidly and cost-effectively produce prototypes. Axial and mixed-flow fans can be powered by a variety of drive systems including brushless DC and hydraulic motors.

Military vehicle fans are subject to the International Traffic in Arms Regulations (ITAR) and may not be exported, released, or disclosed to non-U.S. Citizens inside or outside the United States without prior written approval from the U.S. Department of State.