Liquid oxygen pumps must be designed with careful consideration as LOX is not particularly compatible with many materials typically used in cryogenic machines. Leakage must also be carefully controlled or reduced to very low helium leak rates as oxygen poses a fire hazard. Barber-Nichols’ typical hermetically sealed, long shaft pumps will not work with oxygen as motor materials and our standard high-speed bearing grease are not LOX compatible. BN employs canned motors, magnetic couplings, and advanced seal technologies in the liquid oxygen pumps it produces.

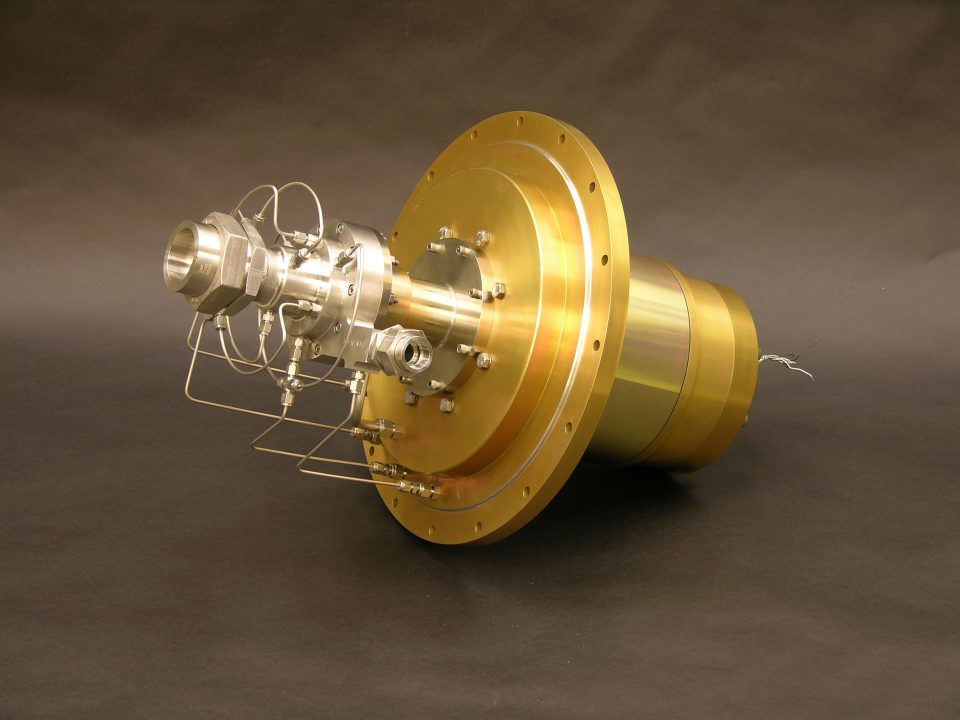

While liquid oxygen’s standard temperature of 90 K is not especially cold in the cryogenic world, it is still often desirable to reduce the conducted heat input to the cryogen. BN modified its long shaft pumps to include magnetic couplings to allow for use with liquid oxygen and other cryogens that must be kept ultra-clean. The liquid oxygen pump shown above includes a magnetic coupling and BN developed this pump for circulating LOX in a laser system. The magnetic coupling isolates the motor and its bearings from the oxygen by the use of a barrier can. The magnetic torque is transmitted from the motor on the outside of this barrier can to the impeller shaft on the inside. All of the materials in contact with LOX are compatible and well-proven in this application.