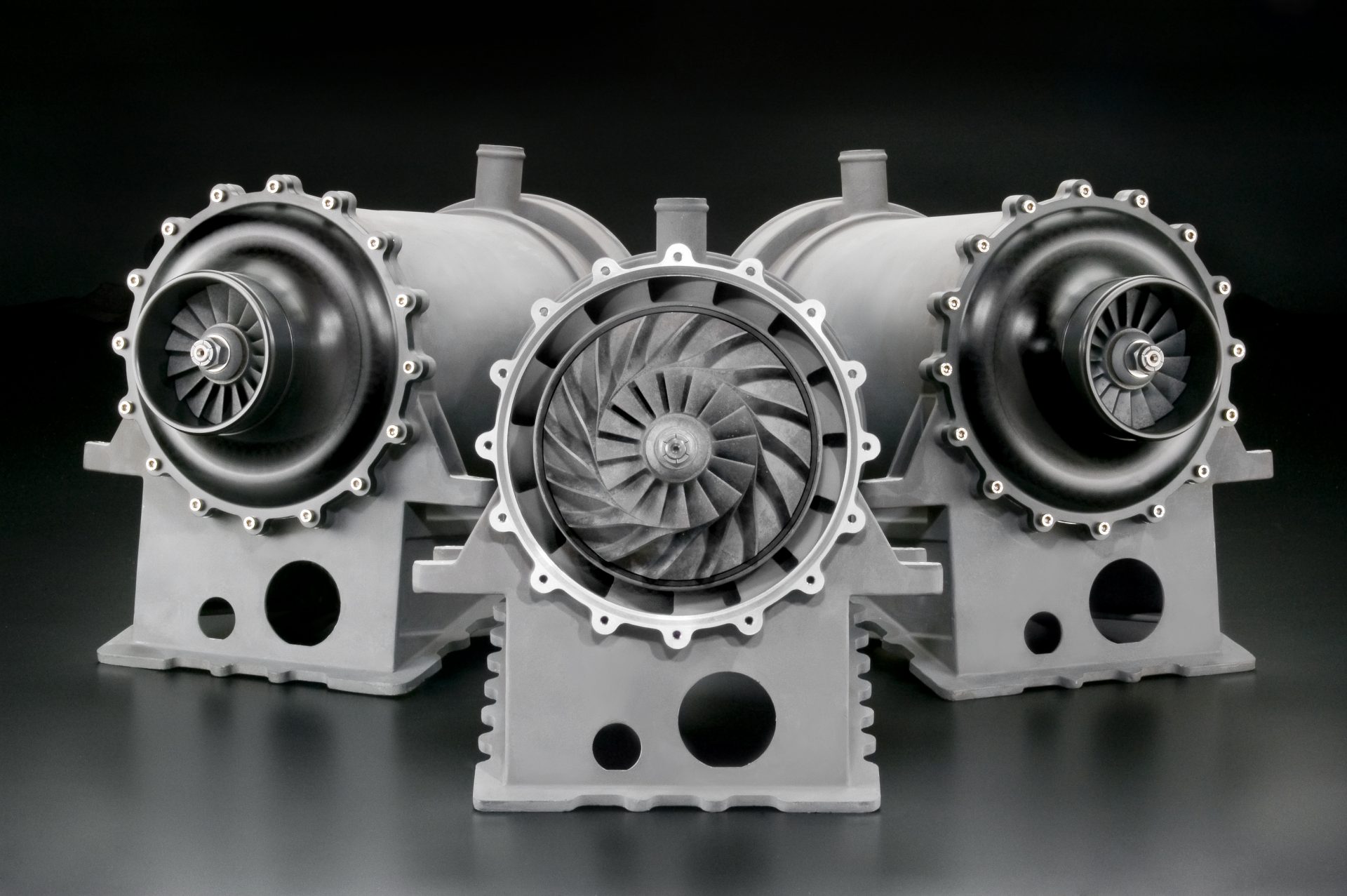

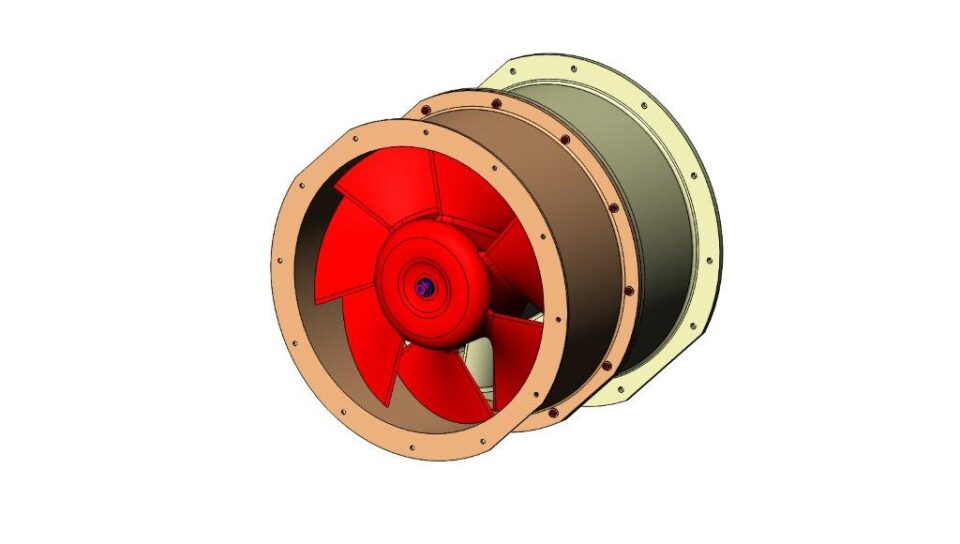

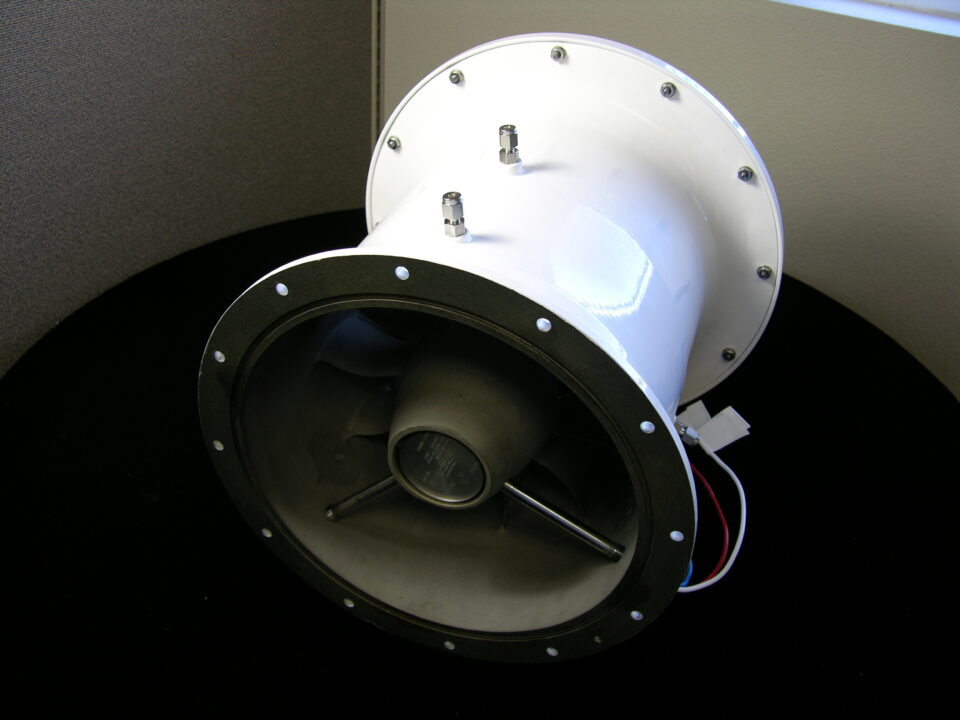

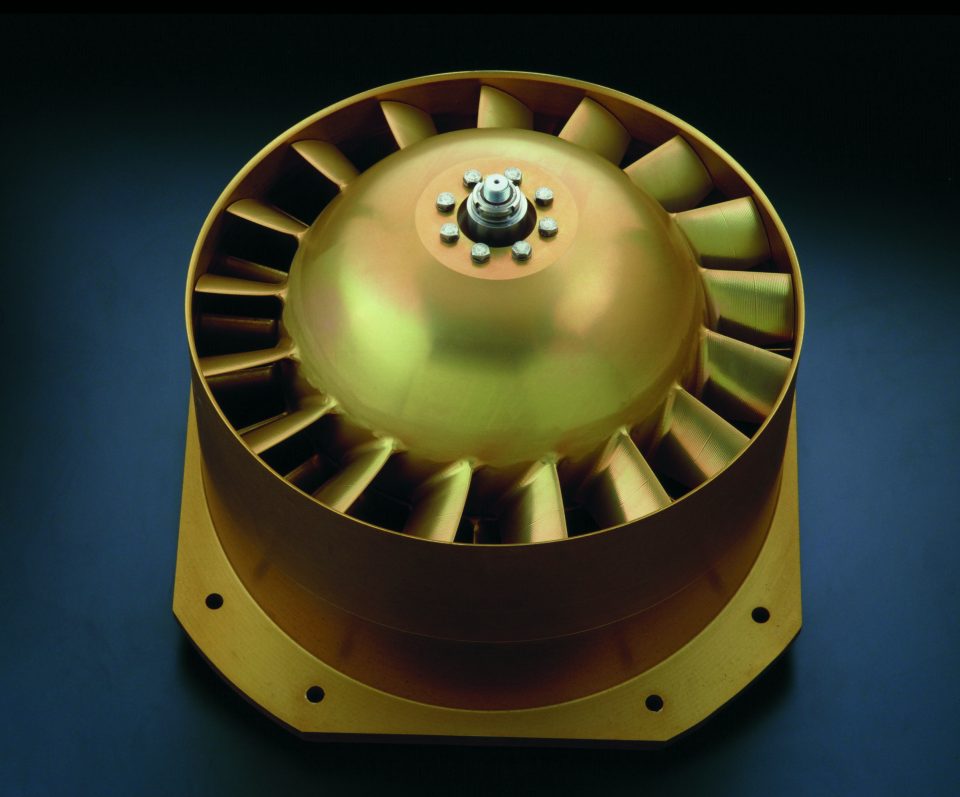

Barber-Nichols (BN) brings extensive experience in designing, producing, and testing fans for the most demanding applications. Whether creating new designs or modifying existing ones, BN applies advanced engineering tools like Meanline and Streamline for conceptual design, BladeGen® for 3D blading, and CFD analysis to optimize performance and noise reduction. Utilizing stereolithography (SLA) investment castings and five-axis machining, BN delivers rapid, cost-effective prototypes for even the most challenging applications.

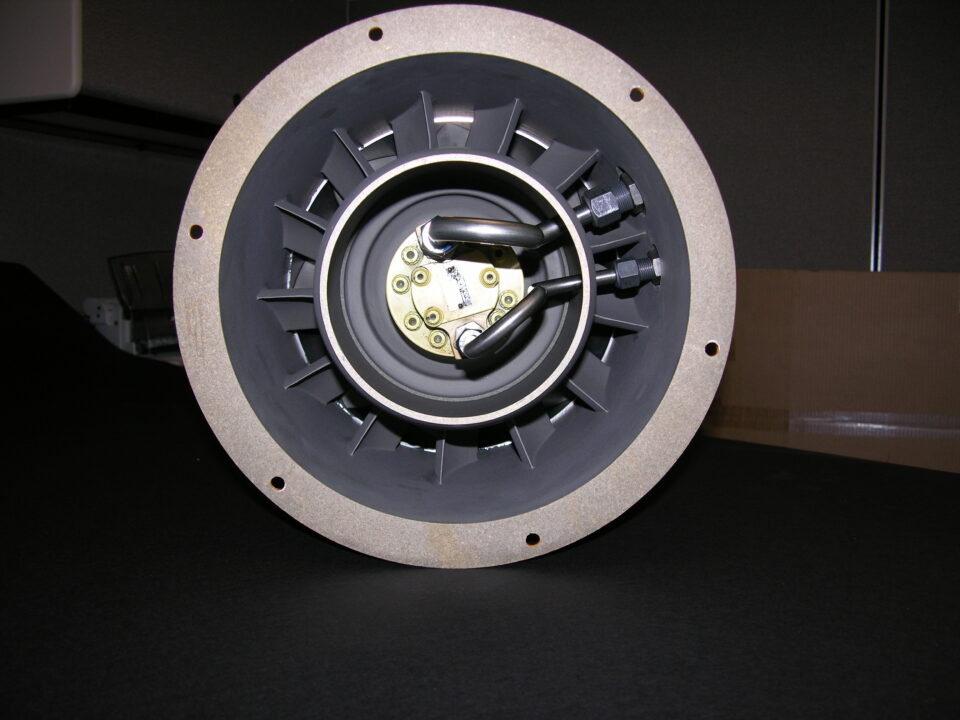

Examples of customized products designed for specific customer applications: