Barber-Nichols designs and produces highly efficient, compact, high-speed Fuel Cell Compressors for both air and anode gas recirculation. BN also provides small, efficient cooling pumps and turbines for fuel cell applications. These machines are customized for specific fuel cells to meet the highest attainable efficiency goals.

Fuel Cell Blowers

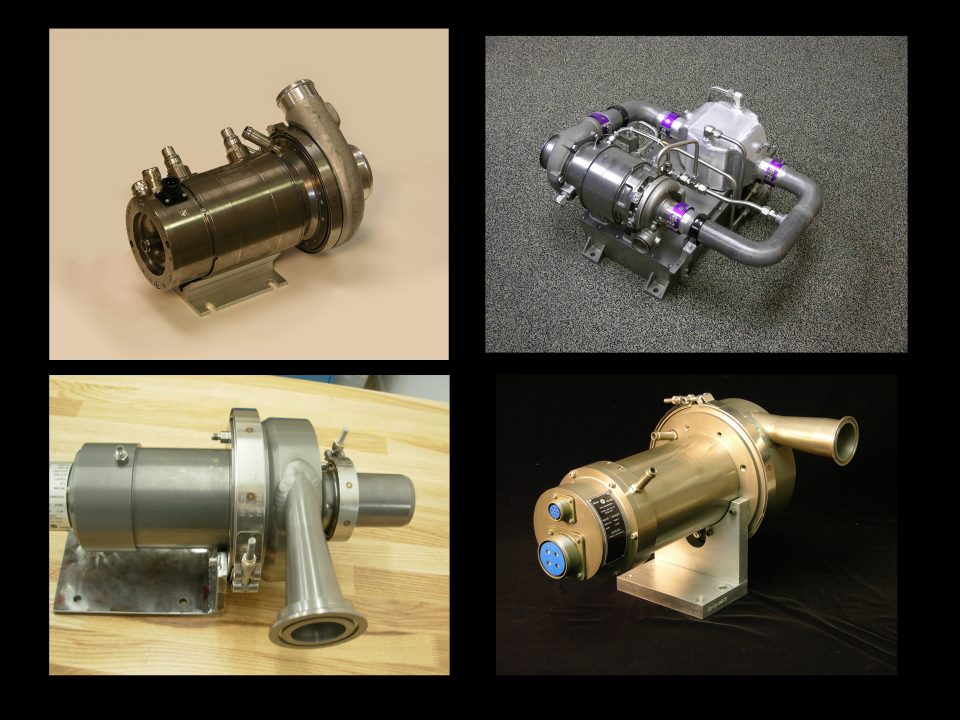

Anode Blowers

Barber-Nichols (BN) makes small, efficient, high-speed Hydrogen Recirculation Compressors for automotive and aerospace applications. These compressors increase fuel cell efficiency by recirculating hydrogen that was not utilized when it passed through the fuel cell. These machines are usually customized to meet very specific application requirements and meet high-efficiency goals. BN’s Hydrogen Recirculation Compressors are typically partial-emission configurations with high-speed brushless DC motors which can operate at speeds up to 50,000 rpm. Automotive and aerospace models have been designed to resist high external temperatures, large shock loads, and corrosion. BN can also provide fully integrated Communication Area Network (CAN) controllers.

Cathode Blowers

BN designs and builds custom air supply (cathode) compressors for automotive and aircraft fuel cell applications. These compressors are normally required to meet high-pressure ratios so these machines typically run at very fast speeds. To meet these high speeds BN has utilized its expertise in the application of foil bearings to run at speeds over 100,000 rpm. In some instances, the machines will be designed to run through 2 stages of compression with inter-stage cooling to meet even higher pressure ratios. These machines usually utilize BN custom-designed high-speed brushless DC motors for maximum efficiency and power density. These models have been designed to resist high external temperatures, large shock loads, and corrosion. BN also provides fully integrated Communication Area Network (CAN) controllers.