Barber-Nichols (BN) specializes in Low-Pressure Liquefied Natural Gas (LNG) Fuel Pumps designed to meet specific project requirements that maximize efficiency and ROI. Applications include LNG fuel pumps for high horsepower engines (e.g. construction and mining equipment, locomotives, and marine vessels), point-of-use liquefaction, fueling stations, and tanker distribution at pressures less than 20 bar (300 psi)*. LNG is a low-cost, domestically produced, abundant, clean-burning alternative to diesel, and it affords users the opportunity to reduce fuel costs and volatility risk while meeting increased air quality standards. Natural gas becomes a liquid at cryogenic temperatures -162°C (-260°F) and BNI brings more than 40 years of cryogenic pump experience to your project.

Low-Pressure LNG Fuel Pumps

In-Line LNG Fuel Pump For Vehicle Fueling & High Horsepower Engines

Submersible LNG Fuel Pump For Vehicle Fueling & High Horsepower Engines

Barber-Nichols submersible cryogenic pumps are compatible with LNG and can be used in low-pressure supply lines for LNG fueling systems. Similar to the in-tank fuel pumps on cars and trucks, these submersible pumps have an open inlet for drawing fuel directly from the tank and boost the pressure for delivery to the high-pressure fuel system.

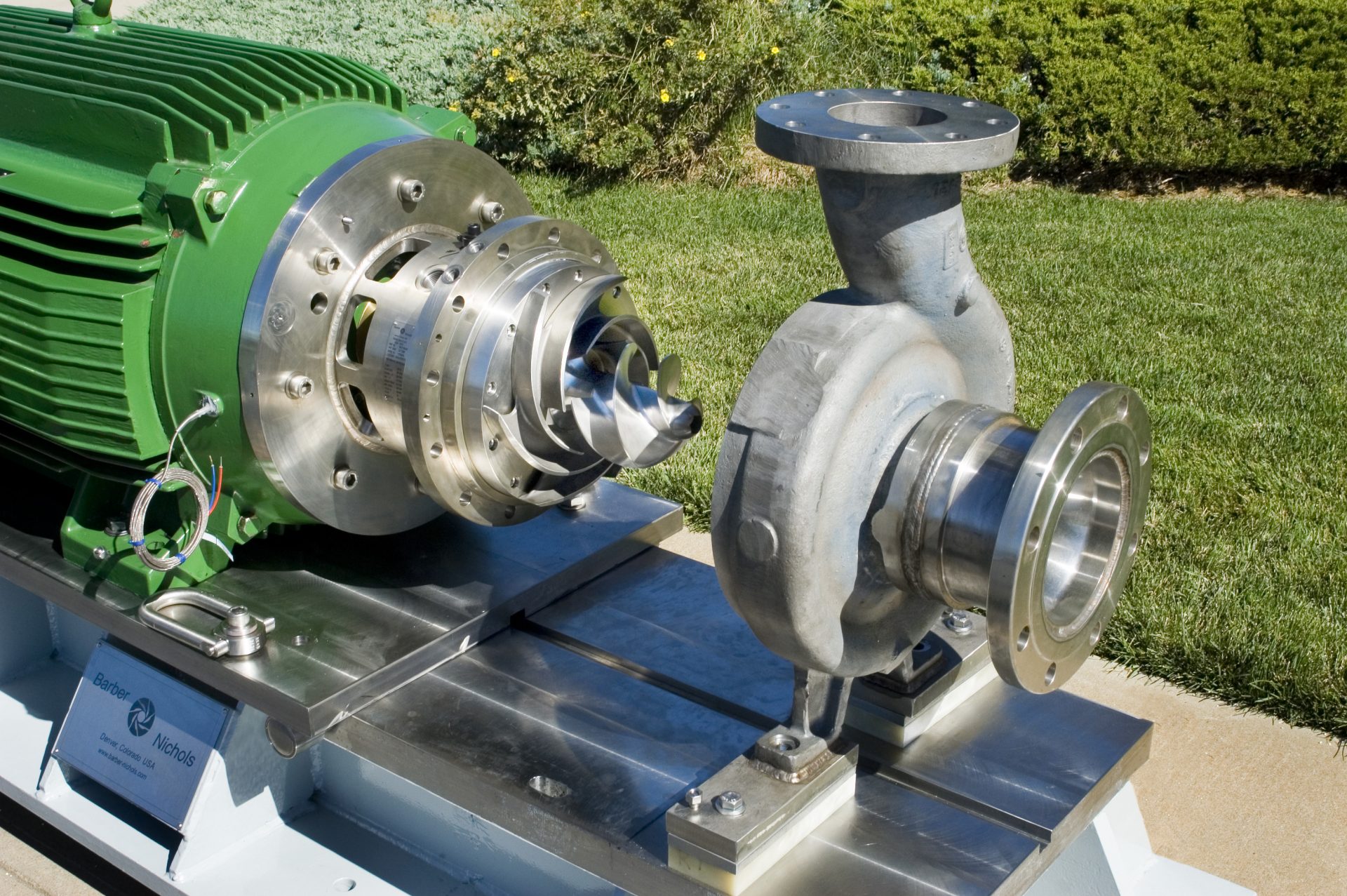

LNG Fuel Bulk Transfer Pump

When large quantities of LNG must be transferred Barber-Nichols bulk LNG transfer pumps are up to the task. With both submersible and externally mounted configurations available Barber-Nichols products offer flexibility to your cryogenic system design.

Low-Pressure LNG Fuel Pump Features

- In-Line & Submersible Configurations Eliminate Shaft Seals

- Variable Speed Control & High Turndown Capability Accommodate Wide Performance Range

- Options For Turnkey Manufacturing Available

*Maximum pressure is dependent on flow rate.