For over 20 years, BN has designed and built more new rocket engine turbopumps than any other company in the United States. This includes design, procurement, manufacturing, and test support from development to flight units all under one roof. Companies choose BN because they have an aggressive schedule and need custom-designed and reliable hardware. BN brings its wealth of knowledge and experience gained from developing turbomachinery for a wide range of applications across multiple industries.

Rocket Engine Turbopumps

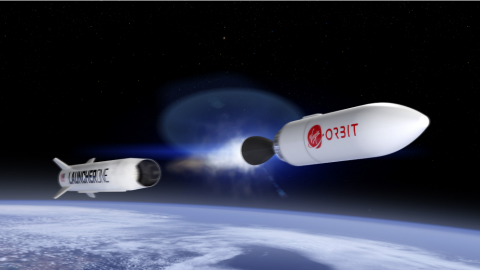

Virgin Orbit's LauncherOne Turbopumps

Barber-Nichols (BN) has successfully developed the Propellant turbopumps for Virgin Orbit’s LauncherOne booster and upper stage liquid rocket engines, the 74,000lbf thrust NewtonThree and 4900lbf thrust NewtonFour. These turbopumps are unique in that they start operation in freefall from a horizontal position at high altitude as LauncherONE is dropped from a carrier aircraft. BN is responsible for the full life-cycle development through manufacturing content including specification refinement, conceptual design, engineering analysis, 3D modeling and drawings, complete manufacturing, assembly, and test support. BN has worked to develop a robust set of analytical tools, manufacturing expertise, quality assurance processes, and critical suppliers to support rapid turbopump development programs.

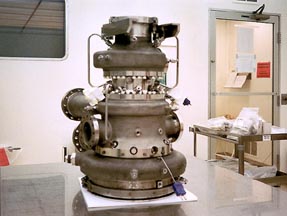

Fastrac LOX/RP-1 Turbopump

BN teamed with NASA’s Marshall Space Flight Center (MSFC) to design and build the turbopump for the Fastrac LOX/RP-1 Engine. The Fastrac Engine produces 60,000 pounds of thrust. Barber-Nichols consulted on the engine design and produced six turbopumps. The Fastrac is part of NASA’s Low-Cost Booster Technologies (LCBT) Program and the development of this engine initially cost approximately $1.2 million – about 1/5 the cost of a similar engine. A hot fire test of the Fastrac Engine was performed at NASA’s Stennis Space Center in March 1999 and the first engine was installed on the X-34 A1 vehicle that was unveiled at NASA’s Dryden Flight Research Center on April 30, 1999.

Bantam LOX/RP-1 Turbopump

BN teamed with Rocketdyne to design and build a second turbopump for NASA’s LCBT Program. This project called for the design and development of a reliable turbopump with decreased recurring costs. The engine produces 60,000 pounds of thrust and the turbopump utilizes two counter-rotating assemblies mounted in a single housing. Additionally, the counter-rotating assemblies operate at different speeds to optimize pump performance. The Bantam Turbopump and the Fastrac Turbopump are two examples that demonstrate the cutting-edge turbopump expertise available at Barber-Nichols.

Merlin LOX/RP-1 Turbopump

Merlin Turbopump In Falcon 9 Launch Vehicle

BN designed and produced the Merlin Turbopump for the SpaceX Falcon Launch Vehicle. The Merlin Engine produces more than 100,000 pounds of thrust at sea level and the turbopump is the lightest in its thrust class. Barber-Nichols used its experience gained on the Fastrac and Bantam projects to rapidly develop the Merlin Turbopump. The first unit was delivered to the customer less than one year after design work began. BN also used Design for Manufacturability principles to increase reliability and significantly cut costs.

Barber-Nichols (BN) entered the space launch industry in 1996, and since that time developed Rocket Engine Turbopumps for NASA, the U.S. Military, and private industry. Since 1966, BN specialized in the design and production of innovative turbomachinery, the use of advanced materials, and Design for Manufacturability. Expertise in these disciplines positioned Barber-Nichols to become one of the world’s leading developers of Rocket Engine Turbopump technology.

Rocket engine turbopumps are subject to the International Traffic in Arms Regulations (ITAR) and may not be exported, released, or disclosed to non-U.S. Citizens inside or outside the United States without prior written approval from the U.S. Department of State.