Barber-Nichols: Specialists in Extreme Environment Compressors and Fans

Since 1966, Barber-Nichols (BN) has specialized in the design and production of high-performance compressors and fans for critical applications. Our products support fuel cells, fuel inserting, vapor cycle systems, environmental control, and life support systems. By leveraging advanced Computational Fluid Dynamics (CFD) analysis, we optimize blade geometry and operational parameters, ensuring maximum efficiency for even the most demanding requirements.

BN’s compressors and fans are engineered for extreme environments, capable of operating in temperatures ranging from 175 ºC (350 ºF) to as low as -270 ºC (-455 ºF). Designed to withstand harsh conditions such as shock, vibration, electromagnetic compatibility (EMC), electromagnetic interference (EMI), and exposure to corrosive environments like salt spray, our solutions are built to last. Additionally, we specialize in high-purity applications, where hermetic sealing offers significant benefits by reducing contamination risks.

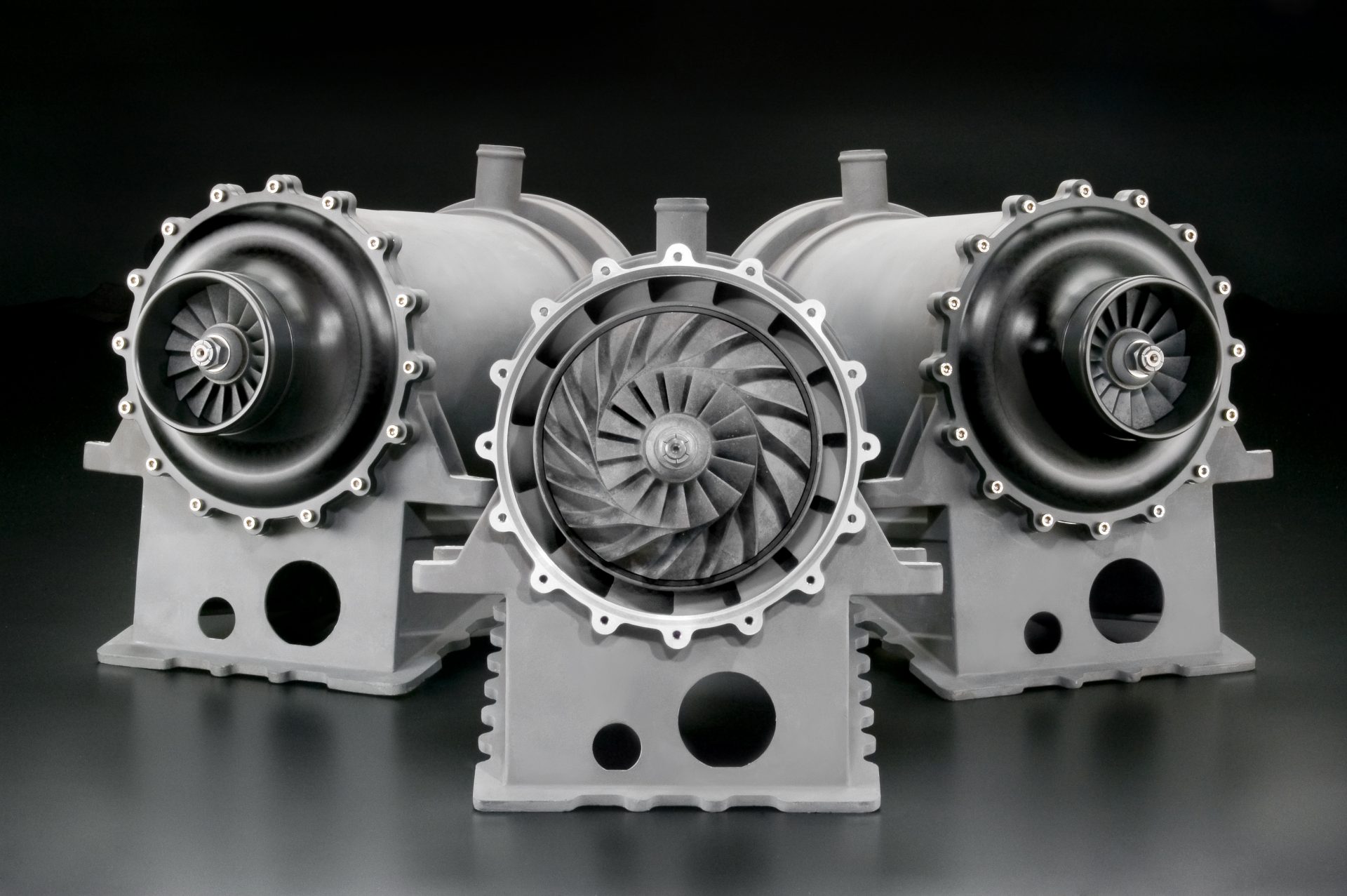

Barber-Nichols’ centrifugal compressors are compact, high-speed, and highly efficient. They have radial flow designs that can be tailored for partial or full emission configurations. Barber-Nichols customizes these compressors to suit specific applications, ensuring they achieve the highest levels of efficiency and reliability.

Barber-Nichols designs fans for applications that require high volumetric airflow with low-pressure ratios, typically using mixed or axial flow designs. These fans are engineered to move large quantities of air while maintaining performance efficiency, even in the most challenging environments.

Our design process begins with advanced software tools like Meanline and Streamline analysis to conceptualize designs, followed by BladeGen® for creating 3D blading. Finally, CFD analysis is applied to optimize performance and reduce noise. We employ Stereolithography (SLA) and five-axis machining for rapid prototyping, ensuring timely and cost-effective production of prototypes.

Fan Capabilities:

Barber-Nichols is a global leader in the design and production of cryogenic compressors, specializing in hermetic, centrifugal compressors for gases like hydrogen, nitrogen, natural gas, and helium, which operate at temperatures as low as 5 K (-450 °F). Hermetic designs eliminate dynamic shaft seals, providing ultra-low leak rates and making the machines explosion-proof. These features make BN’s compressors ideal for cryogenic applications, where performance and reliability are paramount.

Key Features:

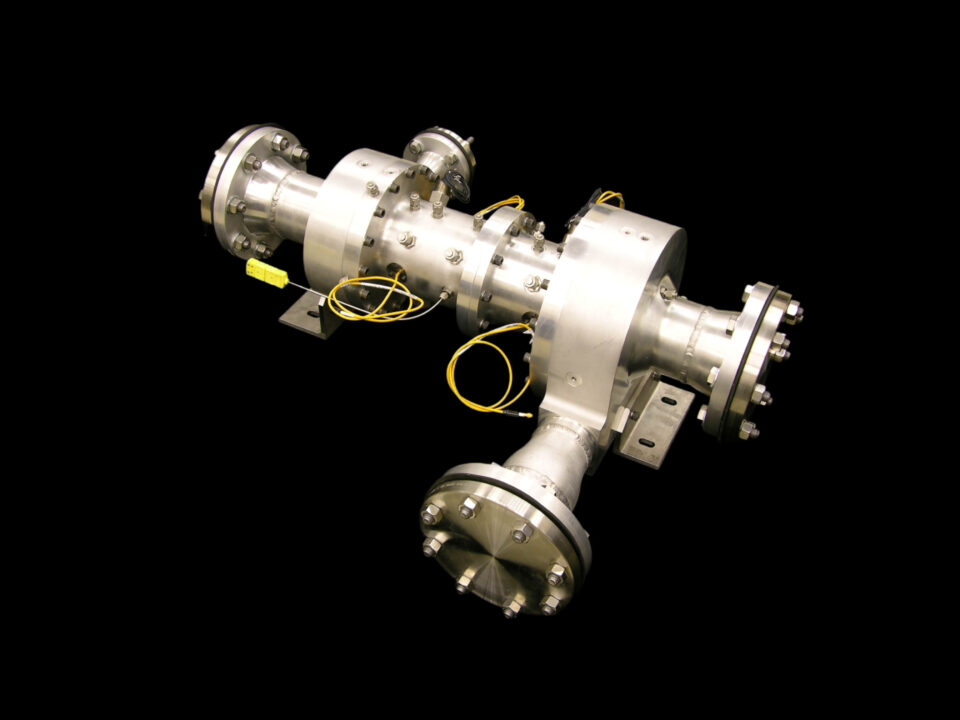

Barber-Nichols specializes in high-performance turbocompressors for a range of industries, including gas turbine engines and process energy systems. Our expertise extends to turbine-compressor-generator assemblies and custom designs for specific applications. In some cases, we can economically modify automotive turbochargers, while in more demanding cases, we develop clean-sheet turbocompressor designs tailored to exacting requirements.